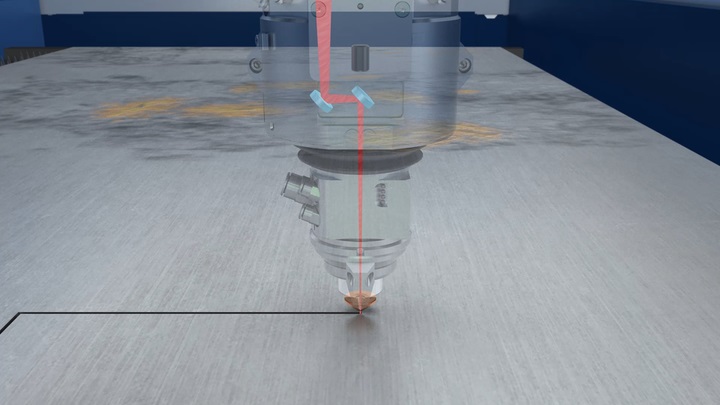

The popularity of the fibre laser Cutting Machine is closely related to its high precision and accuracy. If the cutting accuracy of the fibre laser cutting machine cannot reach, then it is destined to be eliminated. The cutting accuracy of the fibre laser cutting machine is related to the focal point control of the laser cutting machine. Adjusting the focal point of the fibre laser cutting machine is the same as improving the efficiency of the fibre laser cutting machine, and furthermore, it improves the production efficiency of the whole enterprise. Then for improving the cutting accuracy of the laser cutting machine, and accurate adjustment of the focus of the fiber laser cutting machine, we need to understand the focus of the fiber laser cutting machine, the following follow China cut together to see 1. cutting focus on the workpiece above This way we also become negative focus, because the cutting point is not located on the surface of the cutting material nor is it located inside the cutting material, but is positioned above the cutting material. This method is mainly used for cutting materials with high thickness. The main reason for positioning the focal point above the material being cut is that thick plates require a large cutting width, otherwise the oxygen delivered by the nozzle could easily become insufficient and cause the cutting temperature to drop. However, one of the disadvantages of this method is that the cutting surface is relatively rough and not very practical for cutting with high precision. 2. Cutting focal point inside the workpiece This way also become positive focus. When you need to cut the workpiece is stainless steel or aluminium steel plate when the cutting point is commonly used inside the workpiece mode. But one of the disadvantages of this way is that, due to the focal point principle cutting surface, the cutting width is relatively larger than the cutting point on the surface of the workpiece, while this mode requires a large cutting airflow, the temperature should be sufficient, cutting perforation time is slightly longer. So when you choose the material of the workpiece is mainly stainless steel or aluminum light hardness of the material when the choice. 3. Cutting focus on the surface of the workpiece This way also becomes 0 focus, generally common in SPC, SPH, SS41 and other workpiece cutting when using the cutting machine focus selected in close to the surface of the workpiece, this mode of workpiece upper and lower surface smoothness is not the same, generally speaking close to the focal point of the cutting surface is relatively smooth, and away from the cutting focus of the lower surface appears rough. This mode should be determined by the process requirements of the upper and lower surfaces in the actual application.Guangdong China cut CNC Machinery Co., Ltd. is a high-tech industry enterprise specialized in researching, manufacturing and selling the machines as follows: Laser Engraver, Fiber Laser Marking Machine, CNC Router. The products have been widely used in advertisement board, crafts and molding, architecture, seal, label, woodcutting and engraving, stonework decoration, leather cutting, garment industries, and so on. On the base of absorbing the international advanced technology, we provide the clients the most advanced production and perfect after-sale service. In recently years, our products have been sold not only in China, but also as far as Southeast Asia, Middle east, Europe, South America and other overseas Markets.

1. cutting focus on the workpiece above This way we also become negative focus, because the cutting point is not located on the surface of the cutting material nor is it located inside the cutting material, but is positioned above the cutting material. This method is mainly used for cutting materials with high thickness. The main reason for positioning the focal point above the material being cut is that thick plates require a large cutting width, otherwise the oxygen delivered by the nozzle could easily become insufficient and cause the cutting temperature to drop. However, one of the disadvantages of this method is that the cutting surface is relatively rough and not very practical for cutting with high precision. 2. Cutting focal point inside the workpiece This way also become positive focus. When you need to cut the workpiece is stainless steel or aluminium steel plate when the cutting point is commonly used inside the workpiece mode. But one of the disadvantages of this way is that, due to the focal point principle cutting surface, the cutting width is relatively larger than the cutting point on the surface of the workpiece, while this mode requires a large cutting airflow, the temperature should be sufficient, cutting perforation time is slightly longer. So when you choose the material of the workpiece is mainly stainless steel or aluminum light hardness of the material when the choice. 3. Cutting focus on the surface of the workpiece This way also becomes 0 focus, generally common in SPC, SPH, SS41 and other workpiece cutting when using the cutting machine focus selected in close to the surface of the workpiece, this mode of workpiece upper and lower surface smoothness is not the same, generally speaking close to the focal point of the cutting surface is relatively smooth, and away from the cutting focus of the lower surface appears rough. This mode should be determined by the process requirements of the upper and lower surfaces in the actual application.Guangdong China cut CNC Machinery Co., Ltd. is a high-tech industry enterprise specialized in researching, manufacturing and selling the machines as follows: Laser Engraver, Fiber Laser Marking Machine, CNC Router. The products have been widely used in advertisement board, crafts and molding, architecture, seal, label, woodcutting and engraving, stonework decoration, leather cutting, garment industries, and so on. On the base of absorbing the international advanced technology, we provide the clients the most advanced production and perfect after-sale service. In recently years, our products have been sold not only in China, but also as far as Southeast Asia, Middle east, Europe, South America and other overseas Markets.

Link to this article:Three focal modes of fibre laser cutting machines

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^