The price of laser cutting equipment is quite expensive, about 1.5 million yuan or more. With the continuous development of the current storage tank industry, more and more industries and companies have used storage tanks, and more and more companies have entered the storage tank industry. However, since the cost of subsequent processing is reduced, it is feasible to use this equipment in mass production.

Since there is no tool processing cost, laser cutting equipment is also suitable for producing small batches of parts of various sizes that could not be processed previously. Laser cutting equipment usually uses computerized digital control technology (CNC) devices. After using this device, you can use the telephone line to receive cutting data from a computer-aided design (CAD) workstation.

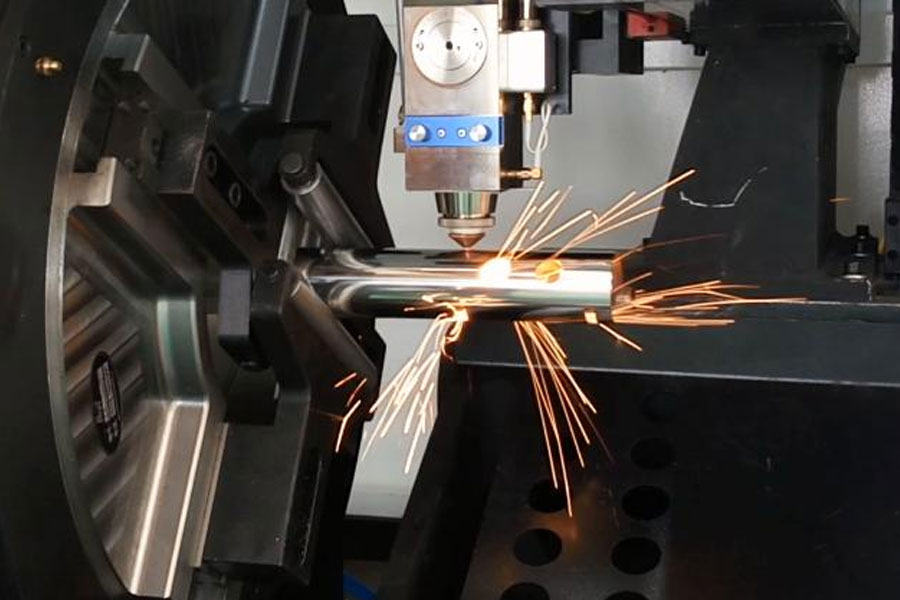

What Is Laser Cutting?Use a high-power density laser beam to irradiate the material to be cut to quickly heat the material to vaporization temperature and evaporate to form holes. As the beam moves on the material, the holes continuously form slits with a very narrow width (such as about 0.1 mm). Finish the cutting of the material.

The Principle Of Laser Cutting

Laser cutting is to irradiate the workpiece with a focused high-power density laser beam to quickly melt, vaporize, ablate or reach the ignition point of the irradiated material. At the same time, the molten material is blown away by the high-speed airflow coaxial with the beam to realize the cutting of the workpiece. open. Laser cutting is one of the thermal cutting methods.

The Classification Of Laser Cut

Laser cutting can be divided into four categories: laser vaporization cutting, laser melting cutting, laser oxygen cutting and laser scribing and controlled fracture.

- 1) Laser vaporization cutting: Use a high-energy density laser beam to heat the workpiece, so that the temperature rises rapidly, reaching the boiling point of the material in a very short time, and the material starts to vaporize and form vapor. The jetting speed of these vapors is very high, and at the same time as the vapor jets, cuts are formed in the material. The heat of vaporization of materials is generally very large, so a lot of power and power density are required for laser vaporization and cutting. Laser vaporization cutting is mostly used for cutting extremely thin metal materials and non-metal materials (such as paper, cloth, wood, plastic, rubber, etc.).

- 2) Laser melting and cutting: In laser melting and cutting, the metal material is melted by laser heating, and then non-oxidizing gas (Ar, He, N, etc.) is sprayed through the nozzle coaxial with the beam to make the liquid metal rely on the strong pressure of the gas Exhaust, forming an incision. Laser melting and cutting do not need to vaporize the metal completely, and the energy required is only 1/10 of that of vaporized cutting. Laser melting cutting is mainly used for cutting some materials that are not easy to oxidize or active metals, such as stainless steel, titanium, aluminum and their alloys.

- 3) Laser oxygen cutting: The principle of laser oxygen cutting is similar to oxyacetylene cutting. It uses a laser as a preheating heat source and an active gas such as oxygen as the cutting gas. On the one hand, the blown gas reacts with the cutting metal to generate an oxidation reaction and release a large amount of oxidation heat; on the other hand, the molten oxide and melt are blown out of the reaction zone to form an incision in the metal. Since the oxidation reaction in the cutting process generates a lot of heat, the energy required for laser oxygen cutting is only 1/2 of the melting cutting, and the cutting speed is much faster than laser vaporization cutting and melting cutting. Laser oxygen cutting is mainly used for easily oxidized metal materials such as carbon steel, titanium steel and heat-treated steel.

- 4) Laser scribing and controlled fracture: Laser scribing uses a high-energy density laser to scan the surface of brittle materials, so that the material is heated to evaporate a small groove, and then a certain pressure is applied, and the brittle material will move along the small groove. split. The lasers used for laser scribing are generally Q-switched lasers and CO2 lasers. Controlled fracture is the use of the steep temperature distribution generated when the laser groove is carved, which generates local thermal stress in the brittle material, causing the material to break along the small groove.

The Features Of Laser Cut

Compared with other thermal cutting methods, laser cutting has the general characteristics of fast cutting speed and high quality. Specifically summarized as the following aspects.

⑴ Good cutting quality

Due to the small laser spot, high energy density and fast cutting speed, laser cutting can obtain better cutting quality.

- ① The laser cutting incision is narrow, the two sides of the slit are parallel and perpendicular to the surface, and the dimensional accuracy of the cut parts can reach ±0.05mm.

- ② The cutting surface is smooth and beautiful, and the surface roughness is only tens of microns. Even laser cutting can be used as the last process without mechanical processing, and the parts can be used directly.

- ③ After the material is laser cut, the width of the heat-affected zone is very small, and the performance of the material near the slit is almost unaffected. The deformation of the workpiece is small, the cutting accuracy is high, the geometric shape of the slit is good, and the cross-sectional shape of the slit is relatively regular. Rectangle. The comparison of laser cutting, oxyacetylene cutting and plasma cutting methods is shown in Table 1. The cutting material is a 6.2mm thick mild steel plate.

⑵ High cutting efficiency due to the transmission characteristics of the laser

Generally, the laser cutting machine is equipped with multiple CNC workbenches, and the entire cutting process can be fully CNC. During operation, only by changing the numerical control program, it can be applied to the cutting of parts of different shapes, which can be used for two-dimensional cutting and three-dimensional cutting.

⑶ Fast cutting speed

Using a laser with a power of 1200W to cut 2mm thick low-carbon steel plates, the cutting speed can reach 600cm/min; for 5mm thick polypropylene resin plates, the cutting speed can reach 1200cm/min. The material does not need to be clamped and fixed during laser cutting, which not only saves tooling and fixtures, but also saves auxiliary time for loading and unloading.

⑷ Non-contact cutting

There is no contact between the torch and the workpiece during laser cutting, and there is no tool wear. Processing parts of different shapes does not need to change the “tool”, just change the output parameters of the laser. The laser cutting process has low noise, low vibration and no pollution.

⑸ There are many types of cutting materials

Compared with oxyacetylene cutting and plasma cutting, there are many types of laser cutting materials, including metal, non-metal, metal-based and non-metal-based composite materials, leather, wood, and fiber. But for different materials, due to their own thermophysical properties and different absorption rates for lasers, they show different laser cutting adaptability. Using CO2 laser, the laser cutting performance of various materials is shown in Table 2.

⑹ Disadvantages

Due to the limitation of laser power and equipment volume, laser cutting can only cut plates and tubes with medium and small thicknesses, and as the thickness of the workpiece increases, the cutting speed decreases significantly. The cost of laser cutting equipment is high and the one-time investment is large.

The Main Features Of Laser Cutting

The workpiece with a narrow slit has a small deformation; the laser beam is focused into a small spot, so that the focal point can reach a high power density. At this time, the heat input by the beam far exceeds the part that is reflected, conducted or diffused by the material, and the material is quickly heated to the degree of vaporization, and evaporates to form a hole. As the beam and the material move relatively linearly, the holes continuously form slits with a very narrow width. The cutting edge is slightly affected by heat, and there is basically no deformation of the workpiece.

During the cutting process, an auxiliary vapor suitable for the material to be cut is added. When steel is cut, oxygen is used as an auxiliary vapor to produce an exothermic chemical reaction oxidizing material with molten metal, and at the same time, it helps blow away the slag in the slit. Compressed air is used to cut polypropylene and other plastics, and inert vapor is used to cut flammable materials such as cotton and paper. The auxiliary vapor entering the nozzle can also cool the focusing lens, preventing smoke and dust from entering the lens holder to contaminate the lens and cause the lens to overheat.

Most organic and inorganic materials can be laser cut. In the metal processing industry where the industrial manufacturing system accounts for a heavy share, many metal materials can be cut without deformation regardless of their hardness. Of course, for high-reflectivity materials, such as gold, silver, copper, and aluminum alloys, they are also good heat transfer conductors, so laser cutting is difficult, or even impossible. Laser cutting has no burrs, wrinkles, and high precision, which is better than plasma cutting. For many electromechanical manufacturing industries, because the modern laser cutting system controlled by the computer program can easily cut workpieces of different shapes and sizes, it is often preferred to the punching and molding process; although its processing speed is slower than that of die punching, But it has no mold consumption, no need to repair molds, and save time for mold replacement, thereby saving processing costs and reducing production costs, so it is more cost-effective to consider overall.

Non-Contact Processing

The laser beam is focused to form a very small point of action with extremely strong energy. There are many characteristics of applying it to cutting. First of all, laser light energy is converted into amazing heat energy and kept in a very small area, which can provide

- ⑴Narrow straight edge slit;

- ⑵The smallest heat-affected zone adjacent to the cut edge;

- ⑶Minimal local deformation.

Secondly, the laser beam does not exert any force on the workpiece, it is a non-contact cutting tool, which means

- ⑴ No mechanical deformation of the workpiece;

- ⑵ No tool wear, and no change of the tool;

- ⑶The hardness of the cutting material does not need to be considered, that is, the laser cutting ability is not affected by the hardness of the material to be cut, and any hardness material can be cut .

Thirdly, the laser beam has strong controllability, high adaptability and flexibility, so

- ⑴It is convenient to combine with automation equipment, and it is easy to automate the cutting process;

- ⑵Because there is no restriction on the cutting workpiece, the laser beam has unlimited profiling cutting ability;

- ⑶It can be combined with a computer to discharge the entire board and save materials.

Adaptability And Flexibility

Compared with other conventional processing methods, laser cutting has greater adaptability. First of all, compared with other thermal cutting methods, as a thermal cutting process, other methods cannot act on a very small area like a laser beam, resulting in a wide incision, a large heat-affected zone and obvious workpiece deformation. Lasers can cut non-metals, while other thermal cutting methods cannot.

Generally speaking, the quality of laser cutting can be measured by the following 6 standards.

- Cutting surface roughness Rz

- The slag size of the incision

- Cutting edge perpendicularity and slope u

- Cutting edge fillet size r

- Towing amount after stripe n

- Flatness F

Scope Of Application

Most laser cutting machines are controlled by CNC programs or made into cutting robots. As a precision processing method, laser cutting can cut almost all materials, including two-dimensional or three-dimensional cutting of thin metal plates.

In the field of automobile manufacturing, the cutting technology of space curves such as car roof windows has been widely used. German Volkswagen uses a laser with a power of 500W to cut complex-shaped thin body panels and various curved parts. In the aerospace field, laser cutting technology is mainly used for cutting special aviation materials, such as titanium alloys, aluminum alloys, nickel alloys, chromium alloys, stainless steel, beryllium oxide, composite materials, plastics, ceramics, and quartz. The aerospace parts processed by laser cutting include engine flame tube, titanium alloy thin-walled casing, aircraft frame, titanium alloy skin, wing stringer, tail wall panel, helicopter main rotor, space shuttle ceramic insulation tile, etc.

Laser cutting technology also has a wide range of applications in the field of non-metallic materials. Not only can cut materials with high hardness and brittleness, such as silicon nitride, ceramics, quartz, etc.; it can also cut and process flexible materials, such as cloth, paper, plastic plates, rubber, etc., such as using laser to cut clothing, which can save clothing 10 %~12%, increase the efficacy by more than 3 times.

Link to this article:Laser Cut - What Is Laser Cutting

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^