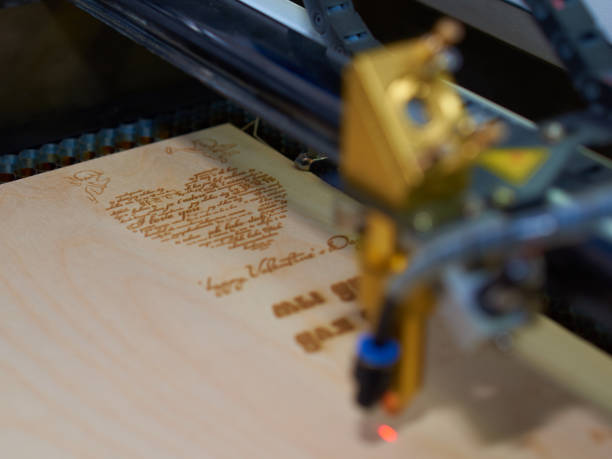

Laser engraving machine for many friends must not be unfamiliar, compared with the traditional engraving method, laser engraving almost achieve the fine engraving of any graphics. Laser engraving machine does not need to replace the carving knife, frustration knife, etc. like the traditional knife carving, no contact processing, will not hurt the material, no tool loss, carving traces proportional, generally applied to wood products, organic glass, glass, stone, crystal, Corian, paper, two-color plate, aluminum oxide, leather, resin, etc.. Many friends will have questions, laser engraving machine why can not be applied to metal materials? The following follow the China cut laser to see the reasons for the analysis.

1. dot matrix engraving

Dot matrix engraving is cool like high-definition dot matrix printing. Laser head left and right swing, each time carved out of a series of dots composed of a line, and then the laser head while moving up and down carved out of multiple lines, and finally constitute a full version of the image or text. Scanned graphics, text and vectorised graphics can all be engraved using dot matrix.

2. vector cutting and dot matrix engraving is different

Vector cutting is done on the outer contour lines of the graphic. We usually use this mode for penetration cutting on materials such as wood, sub-grain, paper, etc. Marking operations can also be carried out on a wide range of material surfaces.

3. Engraving speed

Engraving speed refers to the speed at which the laser head moves, usually expressed in IPS (inches per second), with high speed resulting in high productivity. Speed is also used to control the depth of cut. For a given laser intensity, the slower the speed, the greater the depth of cut or engraving. You can adjust the speed using the engraver panel or by using the computer’s print driver. The adjustment is 1% over a range of 1% to 100%. The advanced motion control system of the Hummer machine allows you to carve at high speed and still get super fine carving quality

4. Engraving intensity

Engraving intensity refers to the intensity of the laser light directed at the surface of the material. For a given engraving speed, the higher the intensity, the greater the depth of cut or engraving. You can adjust the intensity using the engraver’s panel, or by using the computer’s print driver. The adjustment is 1% over a range of 1% to 100%. More intensity equates to more speed. The deeper the cut is also

5. Spot size

The laser beam spot size can be adjusted using lenses with different focal lengths. Small spot lenses are used for high resolution engraving. A large spot lens is used for lower resolution engraving, but for vector cutting it is the best choice. The new machine comes with a 2.0″ lens as standard. Its spot size is in the middle of the range and is suitable for a wide range of applications.

Laser engravers generally use CO2 lasers and the power of the laser tubes used today are in the small to medium power range. The maximum power of the laser tube is 300 W. Originally, the metal absorbs less of this medium wavelength laser. So the laser engraving machine is generally not used to engrave metal.

Guangdong China cut CNC Machinery Co., Ltd. is a high-tech industry enterprise specialized in researching, manufacturing and selling the machines as follows: Laser Engraver, Fiber Laser Marking Machine, CNC Router. The products have been widely used in advertisement board, crafts and molding, architecture, seal, label, woodcutting and engraving, stonework decoration, leather cutting, garment industries, and so on. On the base of absorbing the international advanced technology, we provide the clients the most advanced production and perfect after-sale service. In recently years, our products have been sold not only in China, but also as far as Southeast Asia, Middle east, Europe, South America and other overseas Markets.

Link to this article:Why laser engraving machines cannot engrave metal?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^