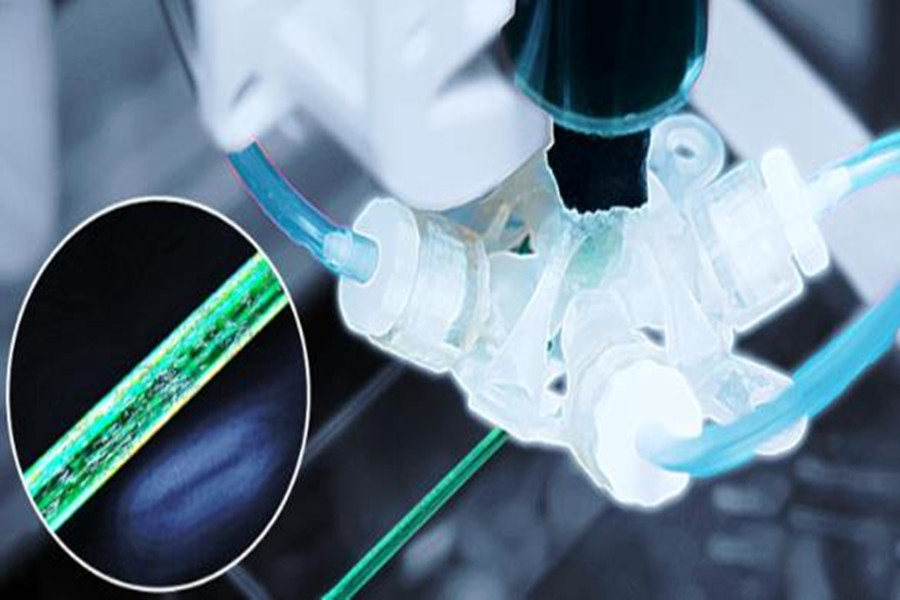

Engineers at the University of Maryland (UMD) have created a new deformable or “deformable” 3D printed nozzle, which was called Frontispiece in the January 5th issue of Advanced Materials Technology.

The team’s deformable nozzle provides researchers with a new method of 3D printing “fiber-filled composite materials”. Materials composed of short fibers can enhance the special properties of traditional 3D printed parts, such as enhancing part strength or conductivity. The challenge is that these properties are based on the direction or “direction” of the short fibers, which so far have been difficult to control in the 3D printing process.

Assistant Professor Ryan Sochol said: “When deforming nozzles are used for 3D printing, the power is on their side actuators. The actuators can expand like a balloon to change the shape of the nozzle and thereby change the direction of the fibers.” UMD A. James Clark School of Engineering, PhD in Mechanical Engineering and Director of the Bio-Inspired Advanced Manufacturing (BAM) Laboratory.

In order to prove their new method, the researchers set their sights on the emerging “4D printing” application. David Bigio, professor of mechanical engineering at UMD, co-author of the study, said: “4D printing refers to a relatively new concept of 3D printed objects that can be reshaped or deformed according to their environment.” “In our work, we studied printing. The expansion of the part after being immersed in water, in particular, whether it is possible to change the expansion characteristics using a deformable nozzle.”

The latest advances in 4D printing rely on materials that are capable of “anisotropic” swelling (swelling more in one direction than the other) and “isotropic” swelling (swelling the same in all directions). Unfortunately, switching between these conditions often requires researchers to print with a variety of different materials.

Connor Armstrong, the lead author of the study, said: “What is exciting is that we found that just by changing the shape of the nozzle during the 3D printing process, a printed material can transition between anisotropic and isotropic swelling. “Armstrong developed this method in UMD’s MS thesis research.

Noah Todd, a co-author of the study and a freshly graduated mechanical engineering student, said: “The important thing is that the nozzle’s ability to deform and even score points on swelling performance is not limited to 4D printing.” We The method can be applied to 3D printing many other composite materials to customize their elastic, thermal, magnetic or electrical properties. ”

Interestingly, in order to build the deformable nozzle itself, the team actually turned to another 3D printing technology called “PolyJet Printing”. This multi-material inkjet-based method provided by the UMD Terrapin Works 3D Printing Center allows researchers to use inflatable side actuators and deformable central channel flexible materials to 3D print nozzles, and then use the shell and the rigid material of the shell 3D printing.

Research co-author and PhD candidate in mechanical engineering, Abdullah Alsharhan, said: “Using multi-material PolyJet 3D printing technology allows us to design nozzles with a certain power range or a set of pressure levels. The nozzle can basically be reproduced in any research laboratory.”

In an application of this new method, the research team is exploring the use of its strategy to achieve biomedical applications, in which bulk printed objects can be reshaped under special stimulation from the body. The team is also in discussions with several Department of Defense laboratories to use deformable nozzles to support the production of weapons for defense and other military systems.

“By providing researchers with an accessible way to perform on-demand control of fiber orientation and final performance of 3D printed fiber-filled composites,” Sochol said, “this work opens the door to new applications of 3D printing. Take advantage of these unique material properties and the unique functions they provide.”

Link to this article: New deformable nozzle can revolutionize 4D printing applications

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. Large scale machining Manufacturer of medical bags, providing 3D design, prototype and global delivery services. Also offering hard cases, semi-hard EVA, soft-sewn cases, pouches and more for OEMs. All cases are made custom according to specifications with infinite combinations of materials, molds, pockets, loops, zippers, handles, logos and accessories. Shockproof, water-resistant and eco-friendly options. Medical parts, emergency response, Electronic parts, corporate, education, military, security, sports, outdoors and construction industries. Services include case concept consultation, 3D design, prototyping,rototyping,CNC Drilling Services and manufacturing.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. Large scale machining Manufacturer of medical bags, providing 3D design, prototype and global delivery services. Also offering hard cases, semi-hard EVA, soft-sewn cases, pouches and more for OEMs. All cases are made custom according to specifications with infinite combinations of materials, molds, pockets, loops, zippers, handles, logos and accessories. Shockproof, water-resistant and eco-friendly options. Medical parts, emergency response, Electronic parts, corporate, education, military, security, sports, outdoors and construction industries. Services include case concept consultation, 3D design, prototyping,rototyping,CNC Drilling Services and manufacturing.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

Link to this article:New deformable nozzle can revolutionize 4D printing applications

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^