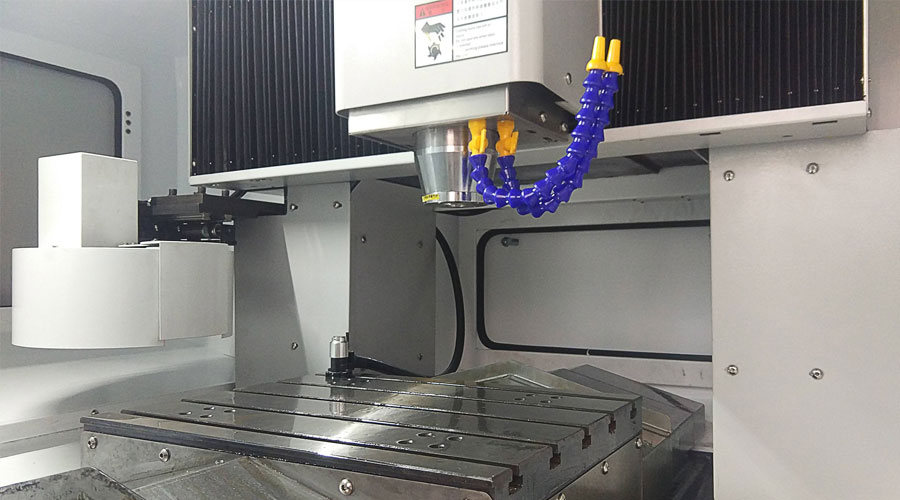

Introduction Of Cnc Carving Machine

| CNC precision engraving machine is a kind of CNC machine tools. Metal engraving machine can perform non-contact cutting and punching on metal or non-metallic plates and pipes, especially suitable for laser cutting of stainless steel plates, iron plates, silicon wafers, ceramics, titanium alloys, epoxy, A3 steel, diamond and other materials . The equipment runs stably and reliably, has good processing quality, high efficiency, simple operation and convenient maintenance. |

The CNC precision engraving machine is very similar to the engraving machine, engraving and milling machine, and machining center (computer gong) in appearance and structure. The following is a comparative analysis of the four:

Conceptually CNC precision machining:

Machining center: It can realize the centralized processing of milling, drilling, boring, reaming and tapping after the workpiece is clamped at one time. The function especially emphasizes “milling”.

CNC precision engraving machining: as the name implies, it can be accurately carved or milled. On the basis of the engraving machine, the power of the spindle and servo motor is increased, and the bearing capacity of the bed is maintained. At the same time, the high speed of the spindle is maintained, and more importantly, the accuracy is high.

Engraving machine: its high spindle speed is suitable for the processing of small tools, the torque is relatively small, focusing on the “engraving” function, such as wood (specially called wood carving machine called wood carving machine), two-color board, acrylic board and other plates with low hardness, It is too suitable for large workpieces with strong cutting. At present, most of the products on the market bearing the name of the engraving machine are mainly processing crafts, which have low cost and are not suitable for mold development due to low accuracy; however, there are exceptions such as wafer engraving machines.

Engraving and milling machine: Engraving and milling machine focuses on engraving and milling, and is a transitional model between precision carving and machining. Compared with precision engraving machines, it has the advantages of stronger rigidity, higher processing efficiency, high power, and suitable for fast and heavy cutting of soft metals. Compared with cnc machining, the advantages are: faster processing of soft metals such as copper and aluminum, and more efficient machining of steel molds. Its disadvantages are not suitable for roughing and heavy cutting of large workpieces. The engraving and milling machine is also developing at a high speed, which is generally called a high-speed machine. It has a stronger cutting ability and a very high machining accuracy. It can also directly process materials with a hardness above HRC60 for one-time molding.

Link to this article: Analysis of Cnc Precision Carving Process

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:Analysis of Cnc Precision Carving Process

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^