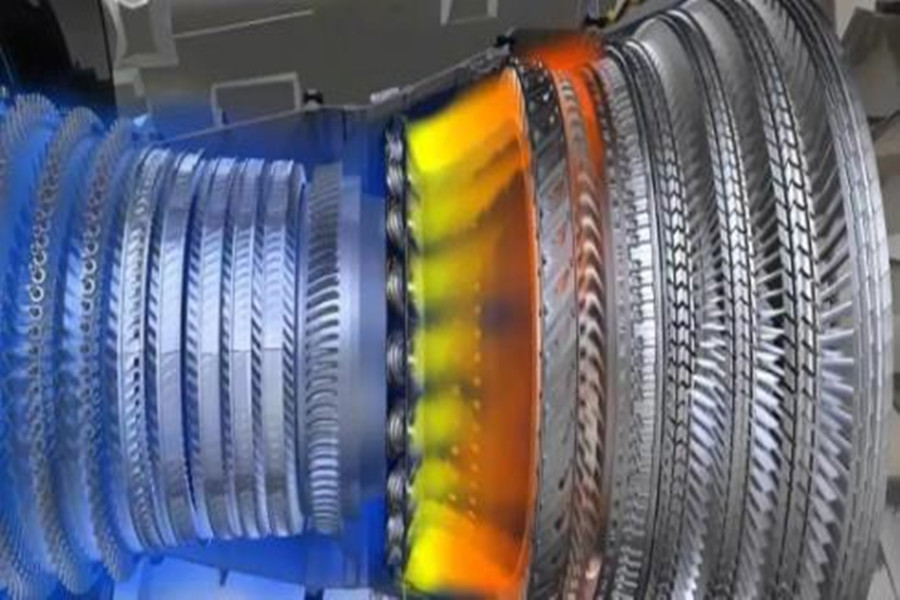

High-temperature alloy materials are widely used in many fields such as aero engines, automobile engines, gas turbines, nuclear power, petrochemicals, etc. due to their excellent oxidation resistance and thermal corrosion resistance.

characteristic

The so-called high-temperature alloy is a type of alloy that can work for a long time at a high temperature above 600°C and a certain stress. Compared with traditional metals, superalloy materials have high temperature and high strength in performance; good oxidation resistance and thermal corrosion resistance; good fatigue resistance, fracture toughness, and good elasticity.

Classification

There are basically three ways to divide superalloys: according to the type of matrix element, according to the type of alloy strengthening, and according to the material forming method.

Classification of superalloys

Preparation Process

High-temperature alloy products are mainly non-standardized, so the production process is more complicated, but it can basically be divided into three steps: smelting, casting and hot processing. The powder metallurgy industry replaces the casting process with hot pressing.

application

High-temperature alloys are widely used in many fields, such as aero engines, automobile engines, gas turbines, nuclear power, petrochemicals, etc., due to their excellent oxidation resistance and thermal corrosion resistance.

Among the many application fields, aerospace still occupies the most important position, accounting for 55% of the total demand, followed by the power industry, accounting for 20%.

Why pay attention to the subdivision track of superalloy?

1. Strategic perspective: superalloy materials are strategic military materials in the aerospace field

Improving the performance of aero-engines, realizing the localization of aero-engines, and solving the “heart disease” of my country’s aviation industry has become an urgent task at the national level.

my country began to develop domestic aeroengines in the 1960s. After ups and downs, China has made great progress from the earliest turbojet-5 and turbojet-14 engines to the current turbofan 10 and turbofan 15 engines. In particular, the finalization of the “Taihang” engine has realized the “three major leaps” of my country’s military aeroengines from the second generation to the third generation, from turbojet to turbofan, and from medium thrust to large thrust. It has the ability to independently develop high-thrust military engines. However, there are still two major problems with domestic aeroengines:

1) Compared with foreign engines, it is found that the thrust-to-weight ratio of domestic turbofan engines, the most important indicator, still lags behind.

In terms of current technology, to increase the thrust-to-weight ratio, the gas temperature must be increased. Every time the temperature of the turbine inlet of an aero engine increases by 100°C, the thrust-to-weight ratio can be increased by about 10%, or the performance can be increased by a whole generation. For commercial aeroengines, every 10% increase in thrust can increase the passenger capacity by 10%; for military aeroengines, the increased thrust of military aircraft will become more mobile and combative.

To increase the operating temperature of aerospace engines, the core method is to use high-temperature alloy materials. The amount of high-temperature alloys used in advanced aero-engines has reached more than 50%, which is known as “the cornerstone material of advanced aero-engines.”

High-temperature alloy refers to an alloy material that can resist oxidation, corrosion, and creep at a high temperature of 600-1200℃, and can work for a long time under high mechanical stress. With the continuous upgrading of aviation equipment in the future, the requirements for the thrust-to-weight ratio of aero engines will continue to increase, and engines will rely more and more on high-performance superalloy materials.

New materials and new processes will contribute more than 50% to the engine with a thrust-to-weight ratio of 12-15. From the perspective of future development, it may even account for 67%. Therefore, the development of high-quality high-performance superalloy materials and the improvement of the process level of superalloy products (for example, the development of blade precision casting process from equiaxed crystal, oriented crystal, to single crystal process) is an inevitable trend for the development of the superalloy industry.

2) my country’s aero-engines still have some imports. It can be said that superalloys are one of the core bottlenecks that determine whether aerospace engines can be mass-produced. The localization of superalloy materials is a prerequisite for domestic aero-engines.

Involving high-temperature alloy products in the field of aerospace and aviation applications, developed countries regard them as strategic military materials, with a high degree of technological monopoly, and strictly prohibiting product exports; however, my country still has a large demand for high-temperature alloys that need to be imported from overseas, which is sufficient to explain my country’s current Domestic high-temperature alloys are still unable to meet the needs of the aerospace industry, and their shortage may have become one of the core factors restricting the mass production of aerospace engines in my country.

Moreover, domestically produced superalloy materials have a certain gap with foreign superalloys in terms of purity, uniformity, batch stability and production cost. They still cannot fully meet the material requirements of high-end equipment, especially aeroengines. Therefore, realizing the localization of high-quality and high-performance superalloy materials is also an important part of the domestic aero-engine industry.

2. From an industrial perspective: my country’s aerospace superalloys have gone from research to a turning point in large-scale localization

1) Demand side: my country’s key models of weapons and equipment have passed the development and finalization stage during the “13th Five-Year “Batch” has entered the stage of “large-scale batch production”.

Under the international order of “great changes unseen in a century and accelerating evolution”, the development of my country’s military equipment has entered a period of accelerated catch-up. The core orientation is to build the ability to win a conventional war. Therefore, missiles and military aircraft are tactical in the context of the building of preparedness capabilities. Equipment is the key equipment procurement direction to fill the gap and strengthen training; the completion of the development and finalization of these equipment during the “13th Five-Year Plan” has also laid the industrial foundation for the massive purchase of equipment and upstream raw materials during the “14th Five-Year Plan” period.

On the whole, the development of domestic superalloys is basically consistent with the development level of domestic aerospace engines.

Therefore, with the gradual entry of new domestic military aircraft and ships in the future, domestic engines will gradually move to the forefront, and the development of domestic superalloy materials is ushering in important opportunities and turning points.

2) Supply side: my country’s superalloy has experienced a process from imitation to introduction and then to independent innovation. At present, my country has formed a certain scale of production base with more advanced technology and equipment, and we also see that many superalloy-related companies are implementing expansion plans in the near future. .

Since the successful trial of the first furnace of superalloy GH3030 in 1956, the research, production and application of superalloys in my country have experienced more than 60 years of development so far. Looking back on the history of more than 60 years, my country’s superalloys have grown from scratch, from imitation to independent innovation, the temperature resistance of alloys has changed from low to high, advanced technology has been applied, new materials have been developed, production processes have been continuously improved, and product quality has been continuously improved. , And established and perfected my country’s superalloy system, so that the high-temperature alloy materials required for the production and development of my country’s aviation and aerospace industries are based in the country, and it also provides high-temperature materials needed for the development of other industrial sectors. my country has become the fourth country in the world with its own superalloy system after the United States, Britain, and Russia.

Domestic units engaged in the production of superalloys are divided into three categories. One is special steel enterprises, such as Fushun Special Steel, Great Wall Special Steel, Baosteel Special Steel, etc.; The Institute of Metals, as well as Steel Research Gona, a professional manufacturer of the Central Iron and Steel Research Institute, and private enterprises such as Tunan Co., Ltd. and Jiangsu Longda. We have seen that many high-temperature alloy-related companies are implementing expansion plans in the near future.

3. Profitability perspective: downstream aerospace heavy volume, upstream military new materials are more profitable

First look at the growth rate of volume: Consumption attribute is one of the core influencing factors for the growth rate of the equipment chain. From the perspective of consumption attribute, “superalloy>aero engine>military aircraft” is superimposed on the demand for domestic substitution. Therefore, the superalloy industry is relative to the downstream The growth rate of military aircraft equipment is even higher.

Compared with military aircraft, the demand for aero engines comes from the increase in the volume of military aircraft, and the increase in the intensity of actual combat training to drive consumption; compared with aero engines, high-temperature parts made of superalloys are more frequently repaired and replaced, and there is also overseas import substitution logic. Therefore, the growth rate of the superalloy industry relative to the military aircraft industry will be higher. The high-temperature alloy listed companies such as ST Fushan Iron and Steel, Steel Research Gona, Tunan Co., Ltd., the growth rate of their high-temperature alloy product revenue will be significantly higher than the growth rate of downstream engine assembly, ie, aviation power business. For example, the CAGR of the high-temperature alloy business-related income from 2014-2019 of Steel Research Gona was 18.4%, and the CAGR of the high-temperature alloy business-related income of Tunan Co., Ltd. from 2016 to 2019 was 24.6%, while the CAGR of the engine business income from 2014 to 2019 was only 8.0%.

Second, look at the growth rate of profitability: Compared with downstream assembly, upstream materials are less affected by the military product pricing mechanism. They are more shelf products and therefore have a relatively market-oriented pricing mechanism. The important thing is that materials are more likely to form scale effects, so high-temperature alloys The profitability of material companies is expected to be stronger than that of downstream assembly.

4. Demand perspective: the military and civilian markets are jointly guided, and the demand for domestic substitutes is strong

Not only in the aerospace field, superalloys are also widely used in the industrial field.

High-temperature alloy materials were initially mainly used in the aerospace field. Because of their excellent high temperature resistance and corrosion resistance, they have gradually been applied to electric power, automobiles, metallurgy, glass manufacturing, atomic energy and other industrial fields, thus greatly expanding high-temperature alloy materials. Application areas.

Divided by downstream demand, the demand for superalloys in the aerospace sector accounts for about 55%, followed by energy and electricity for 20%, and machinery manufacturing for 10%.

At present, according to military and civilian use, the demand for superalloys is 28%. With the acceleration of industrial modernization, superalloys will have many growth points in the industrial field, the proportion of civilian use will increase, and the market space will be huge.

Global dimension: The foreign market for superalloys is basically mature, and the annual growth rate of the global market scale is expected to remain at about 10%.

With the global demand for superalloy materials, the global demand for superalloys continues to rise. According to the Foresight Industry Research Institute, the global superalloy market reached 12.2 billion U.S. dollars in 2018, YoY +4.8%. Since 2012, the global superalloy industry has steadily increased its growth rate and is expected to reach 17.3 billion U.S. dollars in 2024.

In 2019, my country’s superalloy market reached 16.98 billion yuan, a year-on-year increase of 33.52%. The domestic high-temperature alloy production capacity is limited, and there has been a long-term large supply and demand gap.

According to the “2020-2026 China Superalloy Industry Market Special Survey and Investment Prospect Planning Analysis Report”, my country’s superalloy output in 2019 is about 27,600 tons, but the overall market demand for superalloys is about 48,200 tons, and the supply and demand gap is 20,600 Ton. Based on the average price of my country’s superalloys in 2019 of 352,200 yuan/ton, the market size of my country’s superalloy industry is 16.98 billion yuan, a year-on-year increase of 33.52%. We focus on the calculation of the domestic demand for superalloys in the field of aerospace engines. In the long run, the localization of domestic commercial aviation engines will also bring huge demand for superalloys in the market.

Link to this article: High temperature alloys are widely used

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, sheet metal to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, laser cutting,drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, sheet metal to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, laser cutting,drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:High temperature alloys are widely used

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^