The Current Status And Research Analysis Of CAPP Technology

|

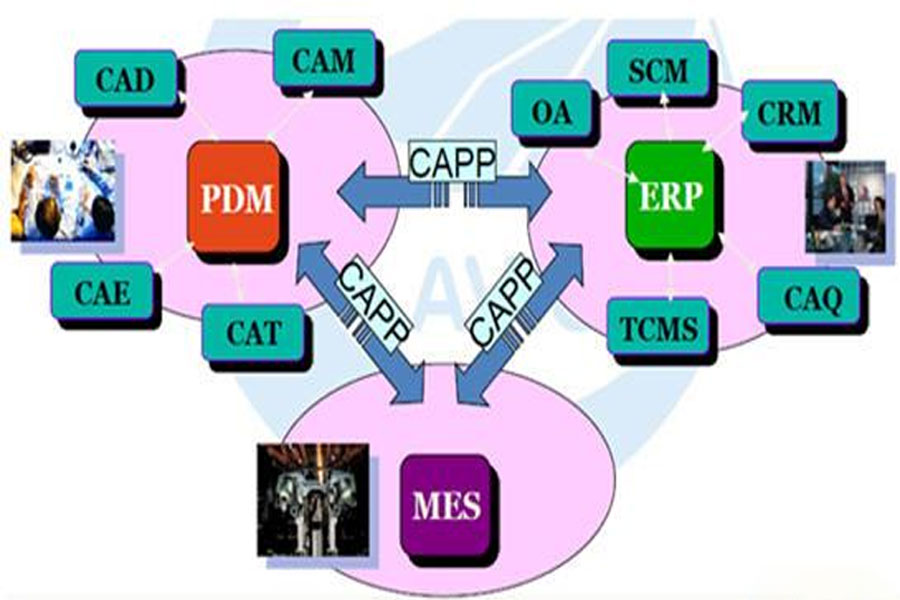

Computer Aided Process Planning (Computer Aided Process Planning, CAPP) refers to the use of computer software and hardware technology and supporting environment, the use of computer numerical calculation, logical judgment and reasoning and other functions to formulate the machining process of parts. Using the CAPP system to complete relevant parameter calculations and generate process routes based on manufacturing information through human-computer interaction has an important role in reducing the labor intensity of staff, improving production efficiency, and improving product standardization. |

CAPP technology originated in the 1960s. In 1965, Niebel applied computer technology to process design. In 1969, Norway officially launched the world’s first CAPP system AUTOPROS and commercialized it in 1973. In 1976, CAM-I launched the CAM-I’s Automated Process Planning system, which was a milestone in the history of CAPP development. In 1985, the International Academy for Production Engineering (CIRP) held a CAPP seminar in Japan to formally define the concept of CAPP. In the following decades, CAPP technology developed rapidly. The CAPP system currently in use at home and abroad is mainly divided into search

There are four types of expert systems: type, derivative type, generative type and CAPP expert system. The main applications are shown in the table below.

| Types | Principle | Application | Problem |

|---|---|---|---|

| Search | Based on the group technical organization, the technical file management system that extracts the standard process according to the number | Retrieving CAPP System for Shaft Parts; CAPP system for French plate parts retrieval |

The number of standard processes is limited, and the process flexibility is poor, and cannot adapt to the current development trend of the manufacturing industry. |

| Derivative | According to the target part and the part geometry and process similarity in the database, the corresponding process knowledge is pushed. | AUTOPROS system, TOJICAP system, WLCAPP system, THCAPP-1 system, etc. | Rely on historical data and lack decision-making logic. |

| Generative | Use logic algorithms to make decisions based on the process rule library, and use decision tables or decision trees to make process method decisions | APPAS system, CAPSY system, BITCAPP system. | The establishment of the rule base requires human definition, and the huge workload results in low utilization rate; the logic algorithm has poor flexibility and is difficult to modify and expand. |

| Expert system | Make decisions based on heuristic algorithms for process knowledge reasoning | MetCAPP system | Effectively improve the processing efficiency of the CAPP system, but the expression of knowledge and decision-making logic are not yet fully mature. |

With the development of the aerospace manufacturing industry, there is an increasing demand for rapid process design of spacecraft parts, and expert systems have gradually become a research hotspot. The main research content is the expression of process knowledge, the automatic establishment and update of the decision rule base, and the intelligentization of process route planning.

Process knowledge is the basis of process design. Traditional process knowledge is usually expressed in natural language and has poor structure, which is not conducive to computer recognition and processing. Therefore, the degree of structure of process knowledge directly affects the work efficiency of the CAPP system. In the research on the expression method of process knowledge, the following methods have been mainly formed, as shown in the following table.

| Method | Scope Of Application | Advantage | Shortcoming |

|---|---|---|---|

| Predicate logic representation | Suitable for describing collective knowledge such as process data | Formal reasoning method with complete logic, classical method based on constraint reasoning | Not suitable for expression process and enlightening knowledge; lack of organizational principles, large knowledge base and low reasoning efficiency. |

| Production Expression | Decision rules for processing method selection, manufacturing resource selection, etc. | Close to the way of human thinking, easy to understand; independent rules, easy to update; clear structure, conducive to users to understand and learn expert knowledge. | Close to the way of human thinking, clear structure and easy to understand; Can not effectively describe complex knowledge. |

| Semantic network representation | Suitable for describing connections between complex process knowledge | The intuitive expression of entity structure, attributes and association relations is similar to natural language, which is conducive to the understanding of complex systems; | It is not suitable for regular knowledge; the scope of expression is limited. Once too many nodes result in a complex network structure, reasoning is difficult to proceed. Ontology representation is suitable for the description of process knowledge information model |

In summary, the current problems of the CAPP system are:

- (1) At present, process knowledge is still mostly expressed in natural language, with poor structure, which is not conducive to the recognition and application of computers. To introduce computer-aided process design and improve the efficiency of process design, the structured expression of process knowledge is the first problem to be solved.

- (2) Due to the immature decision-making logic, the rule base construction method has a low degree of intelligence, which limits the development of the CAPP system and makes the existing system unable to adapt to the “multi-type, small-batch” production model.

- (3) Most CAPP systems are not yet mature in planning methods for the overall process route, and still rely on manual preparation by process personnel, resulting in low process design efficiency. Therefore, how to establish a structured process knowledge model, realize the automatic construction of decision-making rule base and intelligent planning of process routes are the main development directions of the current CAPP system.

Link to this article: The Current Status And Research Analysis Of CAPP Technology

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ CNC shop produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 5 axis CNC milling available.Machining high-temperature alloy range inclouding inconel machining,monel machining,Geek Ascology machining,Carp 49 machining,Hastelloy machining,Nitronic-60 machining,Hymu 80 machining,Tool Steel machining,etc.,. Ideal for aerospace applications.CNC machining produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 3-axis & 5-axis CNC milling available.We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ CNC shop produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 5 axis CNC milling available.Machining high-temperature alloy range inclouding inconel machining,monel machining,Geek Ascology machining,Carp 49 machining,Hastelloy machining,Nitronic-60 machining,Hymu 80 machining,Tool Steel machining,etc.,. Ideal for aerospace applications.CNC machining produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 3-axis & 5-axis CNC milling available.We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:The Current Status And Research Analysis Of CAPP Technology

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^