Since the first industrial robot appeared in the 1960s, it has been constantly updated and tested. Industrial robots integrate advanced technologies such as machinery, electronics, and computers. In the manufacturing process, industrial robots have greatly promoted the process of manufacturing automation. Especially in the automotive industry, robots can already automate processes such as welding, painting, and assembly.

As an important link in the entire manufacturing chain, the foundry industry plays a basic service role in providing parts for other mechanical products. But with the 4.0 industrial revolution and the implementation of the “Made in China 2025” strategy to become a powerful country. Regardless of whether it is domestic or foreign, there are higher requirements for the quality of castings, and the current casting production enterprises are also facing increased labor costs, cleaner production and other requirements. This makes it necessary for foundry companies to change in order to achieve sustainable development. The emergence and gradual maturity of industrial robots are providing new opportunities for the reform of casting enterprises.

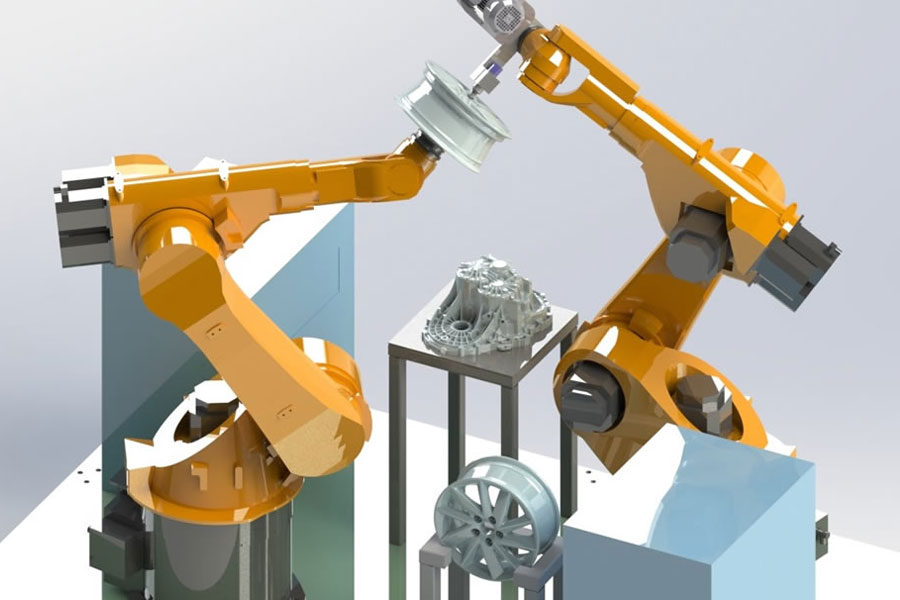

In the current situation of transformation and upgrading of the manufacturing industry, the requirements of increasing efficiency and reducing consumption, green manufacturing, etc. have gradually been paid attention to. Mapping to the foundry industry is the gradual transformation and upgrading from traditional steel materials to light alloy materials such as aluminum alloy and magnesium alloy. Relying on excellent performance, aluminum alloys are widely used. In the traditional casting environment of aluminum alloy, there is a lot of dust, noise, and random discharge of exhaust gas, which brings great pressure to the environment. But since the robots entered the foundry industry in the 21st century, these problems have gradually been solved. For example, in the entire die-casting process, the robot is used to realize the operation processes such as spraying, soup, and picking. The traditional die-casting has high production efficiency and high dimensional accuracy of castings.

The traditional casting mode is manual core setting-casting machine clamping-manual spoon to take aluminum liquid pouring-casting machine flipping product solidification-manual mold ejection-manual pickup-manual coding-natural cooling-manual cleaning-transfer inspection . From the description of this process, we can see that the traditional casting method is human-oriented, which requires high technical level of the casting workers, and a slight deviation will affect the quality of the casting.

In response to this problem, all parts of the world are working hard to solve it through the development of new machinery and equipment. Some enterprises in my country have developed automated production lines for robot gravity pouring, monorail robots, dual-rail robot gravity pouring automated production lines, and overhead aerial rail robot casting automated production lines. Among them, the single-track robot and dual-track robot gravity pouring automated production lines are mainly for products of different categories and tempo requirements, which can flexibly lay out and adjust the production line. The elevated overhead rail robot casting production line is integrated and automated production for the entire casting process, which is suitable for mass products.

At the same time, in order to make the machine production run smoothly, it should also be equipped with a manufacturing management system (MES) for the machine. Through the Internet of Things, the Internet, industrial automation and other information technologies, it can realize the full integration of people, machines, materials, and law in the workshop, and realize the real “Smart Casting”.

At present, we advocate the “fusion” of industrialization and informationization. Intelligent casting is a highly integrated landmark product of industrial technology and information technology. It strengthens the in-depth application of industrial robots in the foundry industry and accelerates the advancement of information technology and the traditional foundry industry. Deep integration can enhance the competitiveness of foundry enterprises and achieve smooth transformation and upgrading.

Link to this article:The Popularization Of Robot Foundry Applications

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:The Popularization Of Robot Foundry Applications

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^