Ultrasonic cutting has the advantages of smooth and reliable cutting, accurate edge cutting, no deformation, no warping, fluffing, threading, wrinkling, etc.

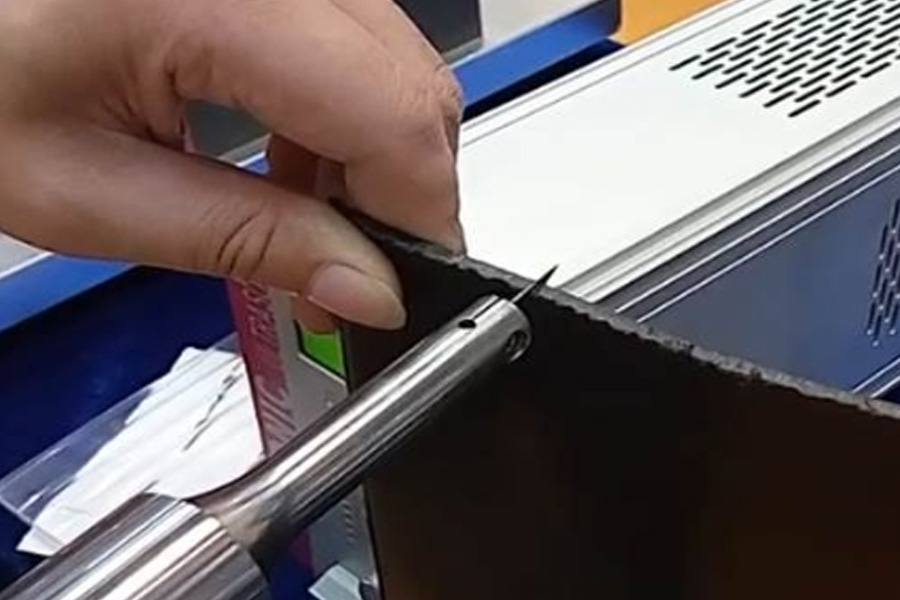

When using ultrasonic technology for cutting processing, the ultrasonic vibrator generates vibration (converts electrical energy into mechanical energy), transfers heat through the HORN (welding head), and rotates and extrudes to the flower wheel (tool) to obtain what is needed for ultrasonic processing effect.

Through the action of ultrasonic waves, the grinding wheel blade generates instantaneous telescopic vibration in the radial direction, so that the abrasive grains and the workpiece can be repeatedly collided under high acceleration in a very short time. As a result, the surface of the workpiece is processed while producing a fine crushed layer, so the processing load of the grinding wheel blade can be greatly reduced. In addition, due to ultrasonic vibration, there is a gap between the grinding wheel blade and the workpiece, thereby greatly improving the cooling effect of the abrasive grains, and by preventing the occurrence of passivation of the abrasive grains and clogging of pores, the processing of the workpiece can be improved. Quality, and extend the service life of the grinding wheel blade.

Link to this article:Ultrasonic Cut What Is Ultrasonic Cutting

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^