For users who are often exposed to FDM 3D printers, when printing models, there will often be a series of printing problems. Among them, there are software problems and hardware problems. Next, Creative 3D will list Several common problems and solutions are for your reference.

1. No consumables in the nozzle before printing

Reason: When most extruders hover at high temperature, the melted consumables in the nozzle will flow out by themselves, which often causes the consumables in the nozzle to drain and form a cavity.

Solution: The core of solving this problem is to ensure that there are sufficient melted consumables in the nozzle of the 3D printer before printing. The most common solution is to add a skirt. Adding a few skirts will draw a few circles on the periphery of the object before printing the object, so that there are enough melted consumables in the nozzle of the 3D printer.

2. Wire drawing or leakage

Reason: Wire drawing is the presence of residual objects when the extrusion head of the 3D printer moves to an open space. The main reason is that the consumables leak from the nozzle when the extrusion head is moving.

Solution: The common way to solve this problem is to draw back. If the draw back is turned on during the slicing, the nozzle will pull the consumables back a certain distance before moving to the next point. When moving to the next point, the consumables will again Return the extrusion head.

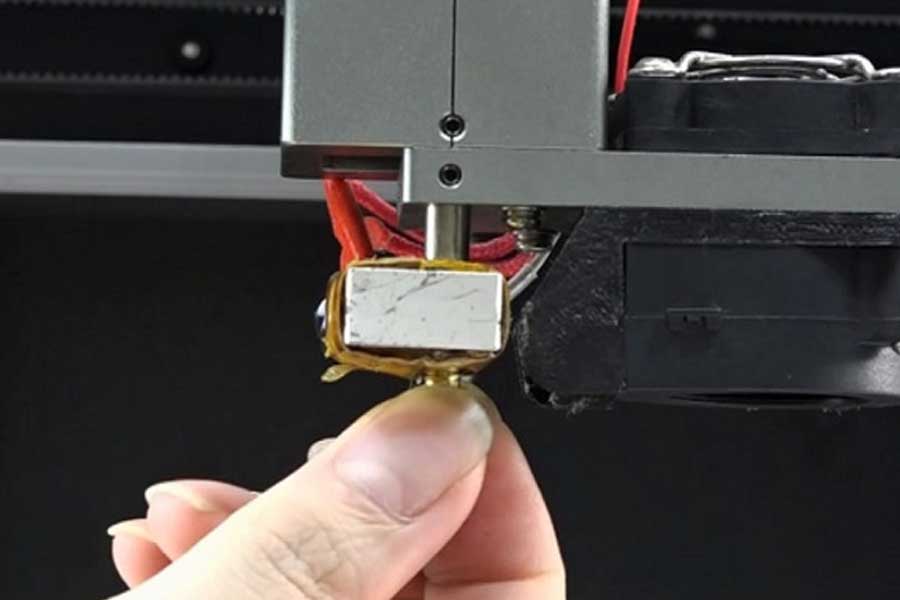

3, the nozzle is blocked

Reason: The temperature setting is unreasonable (PLA temperature is 190-220, ABS temperature is 210-230). The consumables are broken, and other foreign objects are stuck in the position of the feeding motor of the 3D printer print head.

Solution: If the residual material of the print head is fixed, remember to clean up the residual consumables on the print head in time after printing the model. In this case, you can use a little force to feed the consumables down into the feed inlet and squeeze the consumables. If it still does not work properly For spinning, you can use a six-sided wrench to dredge the throat, or use a fine needle to dredge the print nozzle.

4, the 3D printing process is interrupted

Reasons: One is the power supply of the circuit system is interrupted, and the other may be the poor heat dissipation of the 3D printer, which leads to unstable power supply and power failure. If you print with a USB cable, computer failures may occur, such as crashes, card, hibernation, etc.

Solution: first check if it is caused by the power failure; then check if the computer malfunctions when printing via the USB cable: crash, card, hibernation, etc. If the computer is not malfunctioning, check whether the USB cable has magnetic beads. If so, eliminate electromagnetic interference. It is recommended to print on an SD card, and check the platform temperature after interruption. It may be that the power supply is not enough. Try a few more times to see if this problem occurs, then change the 3D printer power supply.

5, the model appears to be warped

Reasons: The reasons for the curling of the model are that the 3D printer platform is too low, the temperature of the nozzle and hot bed is too low, and the nozzle outlet is not cooled enough. It often happens when the first layer of plastic shrinks due to cooling, and one or more corners of the bottom of the model are tilted, making it impossible to attach to the printing platform horizontally, resulting in lateral cracks in the top structure.

Solution: Use a heated printing bed to keep the plastic at temperature and not solidify. You can apply a thin layer of glue evenly on the printing bed to increase the adhesion of the first layer of material, or increase the cushion structure and adjust the platform for reinforcement Adhesion of the printing platform.

6, squeeze out the hair to make a sound during printing

Reason:

1. The selected materials are relatively inferior, uneven in thickness, and more bubble magazines, which are not completely melted.

2. If the temperature of the print head is too high or the use time is too long, the material will be carbonized into small black particles and get stuck in the print head.

3. The thermal performance of the printer is not good.

4. When changing the material, the remaining material is not cleaned up, and will be left near the feeding bearing or the pipe.

5. The feeding gear is worn too much or the residual material is insufficient, resulting in insufficient torque.

6. The GCODE generated by the slicing software does not have a uniform speed, and some sections will have a faster speed, which may cause a click.

Solution:

1. First level it and change to another material to print.

2. Try to unclog the print head with something like embroidery needles.

3. Clean the feeding gear.

4. If you are using a DIY or second-hand machine, it is recommended that you take it apart and learn about the structure principle by the way.

5. If the above problem still cannot be solved, the print head may need to be replaced.

The above are several reasons and treatment methods that frequently appear in FDM 3D printers. Of course, the best way to deal with machine problems is to find after-sales personnel. If you need this service, please contact us.

Link to this article: 3D printer common problems and solutions

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:3D printer common problems and solutions

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^