About three thousand years ago, humans began to cast the first batch of sand castings. Until recently, the technology remained virtually unchanged :

• Place a copy or “pattern” of the desired object in an open steel forming box.

• Pour special type of sand around the model, then tap it firmly into place, and then remove it.

• Cut the gate so that the molten metal and the gate connecting the gate to the mold cavity flow into the mold.

• The core is used to copy parts with internal features.

• Pour molten metal into the mold; when the metal cools, the finished part will be removed.

In short, this is sand casting. But Dave Rittmeyer, a skilled plate maker, will tell you that it’s far more than that. Rittmeyer, customer service and additive manufacturing manager at Hoosier Pattern Inc. in Decatur, Indiana, will also tell you that the industry has changed dramatically in the past decade or so, thanks in part to AM.

Compared with other casting methods, it eliminates many cumbersome steps in the sand casting process, while making the process faster, more flexible and more cost-competitive.

Rittmeyer said: “The lead time of traditional plate making process is best measured within a few weeks and months.” “3D printing has greatly shortened it, sometimes shortened to one or two days. In one example, we are in three A crane case was prepared within this week. It usually takes us 14 weeks. We can print very complex molds and cores, otherwise these molds and cores will not be able to be manufactured.”

Spray successfully

In 1993, MIT researchers invented a 3D printing process called adhesive jetting. Three years later, the company now known as ExOne Inc. took over the binder spray ball and operated with it, permanently changing the sand casting industry.

Figure 1: Most sand castings are made of two-piece molds, which are installed in a steel mold box. The mold box consists of two almost identical, open boxes (drag and upper lid), which are fixed together by pins.

It has developed a cold-hardening adhesive system that deposits sand in layers 0.26 to 0.38 mm thick, and then uses liquid polymers that solidify the sand to bond selective areas together.

Hoosier was founded in 1997 by three skilled pattern makers who used several CNC machines. They bought their first sand printer ExEx S-Max in 2013.

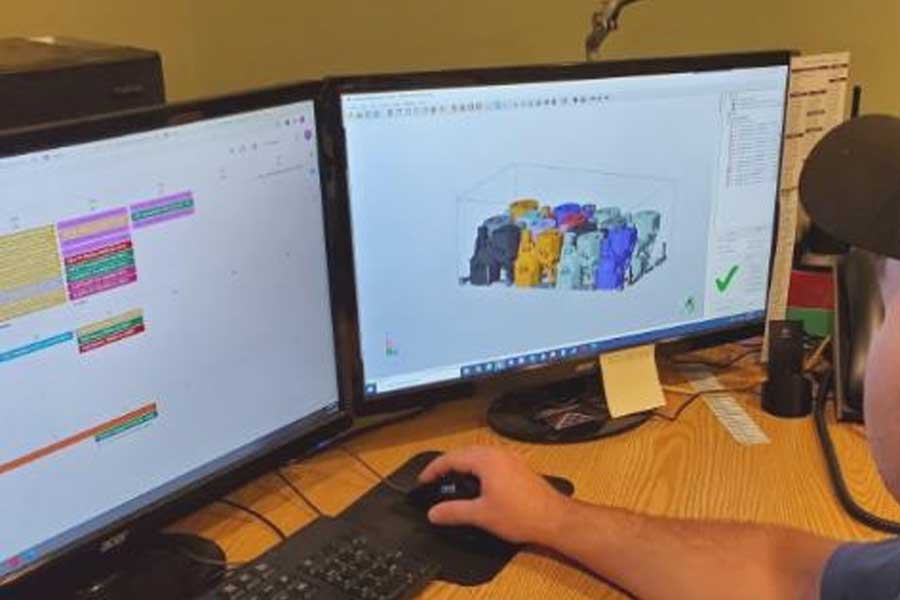

Rittmeyer said: “Today, we have more than 25 machining centers and 4 S-Max sandblasting machines, and about half of our business is 3D printed cores and molds.” “I don’t have exact numbers, but we do every year. Thousands of printed materials are printed.”

The Indiana-based company also operates Stratasys Fortus 450mc FDM machines and 3ntr A2 machines, which are used to make prototypes, small-batch prototypes, and various tools around the store.

3D printing has transformed the company from a regional model room to a global model room. Rittmeyer said that Hoosier Pattern is now shipping 3D printed sand products “to all parts of the world.”

Traditional manufacturing methods (milling, turning and EDM) are still used to produce larger quantities and relatively simple tools, while everything else is sent to one of the company’s 3D printers.

Made in Montrose

Craft Pattern and Mold Inc., based in Montrose, Minnesota, has achieved similar success. The company has been buying 3D printing molds from Hoosier Pattern, but about a year ago, decided to invest in its own system.

“There are several reasons for this,” said Tony Cremers, the company’s president. “Hoosier has done a great job for us, but when you spend a certain amount of money on external services every month, it makes more sense to incorporate this work internally at some point.

“The other part is delivery time. No matter how good the supplier is, having your own printing capabilities determines your response speed to customers.”

3D printing has greatly changed the design process of sand casting, providing engineers with greater flexibility, and “can ignore some basic principles of sand casting.”

Craft Pattern was established 35 years ago as a production model shop. It gradually expanded to prototyping and product development work, and then began pouring a small number of parts. Since then, it has added 4-axis and 5-axis machining services, plastic injection molding and other functions.

Adding a sand print makes a lot of sense. However, the use of this technology requires Craft Pattern to learn some knowledge about the technology.

Steve Shade, the general manager of the store, said that, for example, on 3D printed molds, the surface finish is usually not as good as that of molds made of patterns. “We must also adjust the work process and reconsider some design practices. 3D printing allows us to ignore some of the basic principles of sand casting, allowing us to use traditional tools for drafting, parting and core configurations.

“Our designers are trained and follow the rules of working on the entire profession, which completely changed the way we deal with projects.”

There is no need to physically manufacture the mold, which greatly reduces the timeline for delivery of cast metal parts.

Whether it is made of metal, plastic or sand, anything 3D printed is usually more expensive. “So you can’t just say’Let’s print everything’, because from the perspective of total purchase cost, it is not yet competitive.”

Using traditional tools, the cost of patterns and core boxes can be shared, thereby reducing the cost of parts relatively quickly as the number increases. On the other hand, for 3D printing, the cost of each part is quite fixed according to the amount of sand printed, so economies of scale have not yet been achieved.

“Still, if you want to buy a few pieces or parts with complex geometries tomorrow, then 3D printing is a good choice,” Shade said.

Kramers agreed. He said: “This undoubtedly makes us more flexible.” He added that the workshop can quickly change direction, even turning parts around the next day. Moreover, “It has greatly improved our core manufacturing. In the past, we might have made five or ten independent cores, and then glued them together, and now we can print them all as one piece. In saving labor, This is a huge advantage between the quality of the parts and the control of the entire process.”

Link to this article:

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:3D printing eliminates the tedious work in the sand mold casting process and shortens the processing cycle

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^