3D printing has begun to be applied in many industries.

| 3D printing technology is now very common in our daily manufacturing operations. From the initial tens of thousands of ordinary 3D printers to thousands of today’s, the reduction in equipment prices has also led to an increase in the popularity of 3D printing technology, and the popularity of technology has also driven the development of technology. 3D printing has begun to be applied in many industries. |

3D printed spine bone

There are still many cases in which 3D printing technology is applied in the medical machining industry. It is more common to design and manufacture medical devices. Even more high-tech, there have even appeared biomimetic bones that can “grow and develop” in living organisms (by Wang Yanen, Northwestern Polytechnical University, China) The professor team recently published a paper in the British magazine “Polymer” and body tissues such as heart and liver.

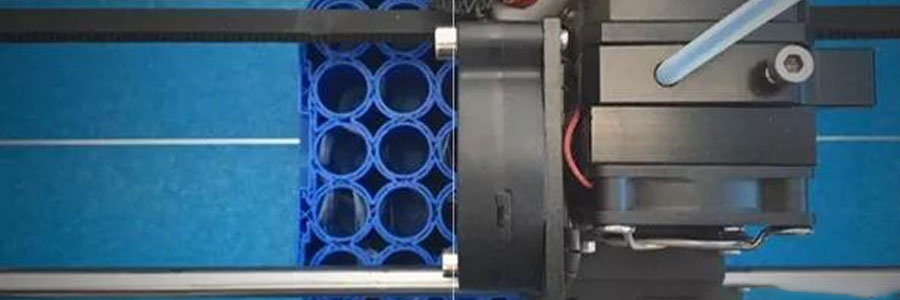

3D printed adapter

Compared with the printing of body tissues, 3D printing is more about the development and production of medical devices. For example, the adapters in some machines of our Baiyang centrifuge are made by 3D printing.

3D printing surgery auxiliary guide

Tumor resection is performed according to the tumor boundary of the imaging data. In actual operation, sometimes the resection range is insufficient or the resection range is too large, which is related to the loss of normal anatomical structure, complex anatomy and microscopic tumor. The use of 3D printed osteotomy guides can more accurately remove tumor boundaries, reduce the recurrence rate of tumors, and preserve as much autologous bone tissue as possible for prosthetic reconstruction.

3D printed bone model

Using the 3D printed bone tumor model, the surgeon can more clearly and intuitively observe the local anatomy of the tumor, the extent and boundary of the tumor, and the adjacent relationship with the local plexus and vascular bundle, and the three-dimensional association with the adjacent internal organs. . Second, on the 3D printed bone model, a surgical simulation can be performed to repeatedly demonstrate and confirm the optimal surgical plan.

The 3D printed bone tumor model allows doctors and patients to communicate preoperatively more intuitively, including specific surgical procedures and possible difficulties during surgery, possible postoperative complications, etc., to improve overall treatment compliance. In addition, the physical model of the disease is more conducive to the medical education of medical students, and the 3D model is better than the 3D image.

PTJ Shop Supply Precision specialty and micro CNC machining services for the medical machining industries. Works with various exotic metals such as aluminum, magnesium, iron, steel, carbon fiber, platinum, cobalt, yttrium, chrome, titanium and tungsten. Capable of micromachining parts under 0.005 in. size and 0.002 to 0.30 in. dia. Medical machining is suitable for hearing aids, cochlear implants, neurostimulators, pacemakers, implantable defibrillators and surgical tools.

Link to this article: 3D printing service machining in the medical device industry

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:3D printing service machining in the medical device industry

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^