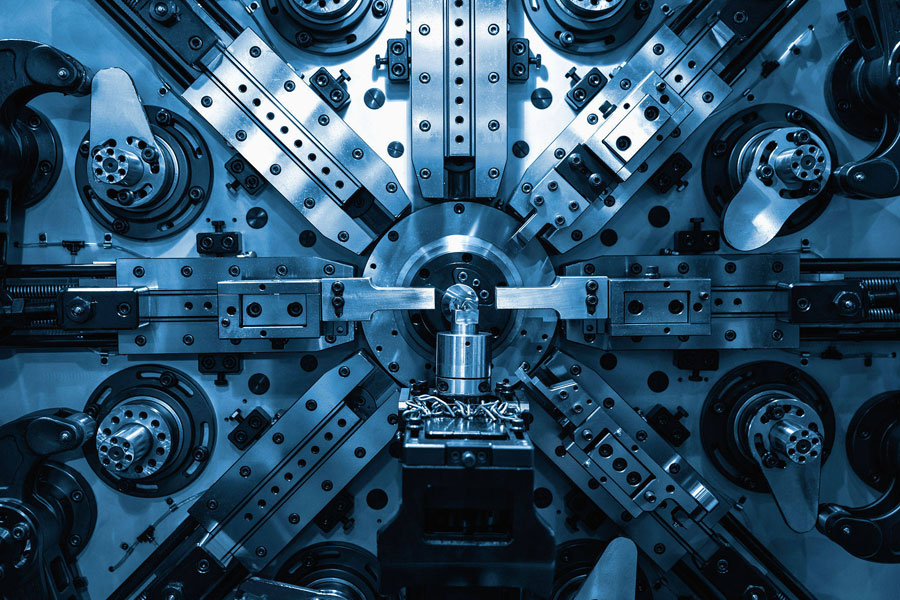

4 Kinds Main Applications Of High-End CNC Machine

|

The “National Medium and Long-term Science and Technology Development Plan Outline (2006-2020)” clearly stipulates that the major scientific and technological projects of “high-end CNC machine tools and basic manufacturing equipment” should “focus on the development of high-end aerospace, shipbuilding, automobile and power generation equipment manufacturing. “Numerical control machine tools”, “gradually improve my country’s independent development capabilities for high-end CNC machine tools and basic manufacturing equipment to meet the basic needs of major domestic industries for manufacturing equipment.” The special implementation plan proposes that by 2020, independent development capabilities for the main products of high-end CNC machine tools and basic manufacturing equipment will be formed, the overall technical level will enter the international advanced ranks, and some products will be internationally advanced. Establish a complete R&D capability for functional components and supporting facilities; form a technological innovation system with enterprises as the main body and a combination of industry, academia and research; train and establish a high-quality R&D team; manufacture aerospace, shipbuilding, automobiles and power generation equipment 80% of the required high-end CNC machine tools and basic manufacturing equipment are in China. In order to more accurately and comprehensively grasp the latest development of the industry, to further understand the needs of key users and the development of the machine tool industry, and to provide a reference for the implementation of special projects, the China Machine Tool Industry Association was commissioned by the Industry Department of the National Development and Reform Commission to organize more than 30 Industry experts. From June to July 2008, under the leadership of the main leaders of the Machine Tool Association, a special survey was conducted on 61 companies and institutions in the aviation, shipbuilding, automotive, power generation equipment and machine tool industries, with a total of 4 research groups. Through in-depth on-site investigations and communication between industry users, we have a clearer understanding of the development of these user industries, the characteristics of typical parts, and the requirements for equipment. |

Aviation Industry Involved In CNC Machine

The structural feature of typical parts in the aviation machining industry is a large number of thin-walled structures with complex shapes. In order to improve the maneuverability of aircraft, increase payload and range, reduce costs, carry out lightweight design, and widely use new lightweight materials, the performance requirements of materials are getting higher and higher. Currently, aluminum alloys, high-temperature alloys, titanium alloys, high-strength steels, composite materials, engineering ceramics, etc. being widely used. Thin-walled parts and honeycomb parts with complex structures have complex shapes, many holes, cavities, grooves, reinforcing ribs, etc., and have poor process rigidity.

According to the structural characteristics and machining requirements of the machined parts in the aviation industry, there are five-axis linkage machining centers with A, B swing angles or A, C swing angles, high-speed machining centers, large double vertical machining centers, large CNC gantry boring and milling machines, Precision CNC lathes, large CNC precision vertical turning centers, turning-milling composite machining centers, blade disc high-efficiency machining centers, end-face arc grinders, high-speed rotor blade tip grinders, slow-feed powerful grinders, broaching machines, related electrical machining machine tools, Laser cladding machining machine tools, multi-mode multi-point forming presses for plate-shaped parts, directional single crystal melting furnaces, electro-hydraulic beam equipment, etc. is compulsory. The machine tool requires sufficient rigidity, simple operation, and clear man-machine interface. In order to reduce the impact on the accuracy of corner machining, spline interpolation and uniform process control are required, as well as online measurement and simulation functions.

Shipbuilding Industry Involved In CNC Machine

The key machining parts of large ships are concentrated on the base, frame, cylinder block, cylinder head, piston rod, crosshead, connecting rod, crankshaft, transmission shaft, rudder shaft and propeller (propeller) of high-power diesel engine. The key machining parts are made of special alloy steel, usually processed in small batches, and the machining yield is required to be 100%. The key machining parts have the characteristics of heavy weight, complex shape, high precision and high machining difficulty. The machining of key parts of large ships requires heavy and super heavy CNC machine tools and special machining machines with high power, high torque and high reliability, as well as multi-axis, heavy and super heavy CNC gantry boring and milling machines, large cyclone lathes, and CNC heavy gantry milling machines. And heavy-duty CNC floor boring machine, CNC lathe, grinder, deep hole drilling machine, large steel plate stamping, pickling, heat treatment and flame Cutting Machine. The machining of heavy and super heavy crankshafts and large propellers is typical, requiring super heavy CNC special machine tools and super heavy multi-axis linkage machine tools.

Automotive Industry Involved In CNC Machining

The production line of automobile engine and body stamping parts has the characteristics of continuity, high efficiency and high reliability. The automotive industry eagerly hopes that machine tool manufacturers can specialize in the technical characteristics of automotive machining parts, and through mutual communication with the automotive industry, jointly develop a set of modular, serialized, and turn-key flexible production lines.

The flexible production line is responsible for the machining of key machining parts such as automobile engine cylinder blocks, cylinder heads, crankshafts, connecting rods, camshafts, boxes, etc. As an object. It is a modular, rapid assembly and reconfigurable production line suitable for mixed-flow production. Master the integrated technology of performance evaluation, error traceability, quality control and management. Developed high-speed precision machining center, fine boring machine, cylinder bore precision grinder, crankshaft dynamic balancing machine, crankshaft journal rolling machine, connecting rod breaker, crankshaft internal and external milling machine, crankshaft high-speed grinder, etc. High-speed picking robots and auxiliary equipment, such as cleaning machines with deburring function, handling robots, laser welding machines, cylinder liner presses, online inspection equipment, etc. High-speed horizontal machining centers, CNC lathes, CNC grinders and other CNC machine tools require stable accuracy and reliable performance, and the CMK value index requires greater than 1.67.

Power Industry Involved In CNC Machining

The key components of power generation equipment are heavy in weight, special in shape, high in precision, difficult to process, and expensive. The price of a single piece far exceeds the price of a heavy-duty CNC machine tool. For example, the pressure vessel of a nuclear power plant weighs 400-500 tons, and the rotor of a large steam turbine and generator weighs more than 100 tons, which requires more than 30 years of reliable work. Therefore, the machine tools required to manufacture key components of power generation equipment have the characteristics of large specifications, high rigidity, and high reliability. Need to provide a variety of ultra-heavy CNC machine tools and special machine tools, such as large CNC vertical lathes, large CNC horizontal lathes, CNC floor milling and boring machines, gantry boring and milling machines and machining centers, CNC drilling machines, large stamping equipment and CNC pipe benders. For some specific machining parts, the machine tool requires multi-axis-controlled five-axis linkage and compound machining functions.

Link to this article: 4 Kinds Main Applications Of High-End CNC Machine

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ CNC shop produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 5 axis CNC milling available.Machining high-temperature alloy range inclouding inconel machining,monel machining,Geek Ascology machining,Carp 49 machining,Hastelloy machining,Nitronic-60 machining,Hymu 80 machining,Tool Steel machining,metal enclosur etc.,. Ideal for aerospace applications.CNC machining produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 3-axis & 5-axis CNC milling available.We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ CNC shop produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 5 axis CNC milling available.Machining high-temperature alloy range inclouding inconel machining,monel machining,Geek Ascology machining,Carp 49 machining,Hastelloy machining,Nitronic-60 machining,Hymu 80 machining,Tool Steel machining,metal enclosur etc.,. Ideal for aerospace applications.CNC machining produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 3-axis & 5-axis CNC milling available.We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:4 Kinds Main Applications Of High-End CNC Machine

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^