Description Of InconelX-750

|

Inconel X-750 alloy is mainly a nickel-based superalloy that is age-strengthened with γ ′ [Ni3 (Al, Ti, Nb)] phase. It has good corrosion resistance and oxidation resistance below 980 ℃, and a high Strength, below 540 ℃ has good relaxation resistance, but also has good forming properties and welding performance. |

The alloy is mainly used for the manufacture of aeroengines that work below 800 ° C and require high-strength corrosion-resistant rings, structural parts, bolts and other parts, and those that work below 540 ° C with moderate or low stress and require relaxation resistance Springs and coil springs. It can also be used to manufacture gas turbine turbine blades and other parts. The available varieties are sheet, strip, bar, forging, ring, wire, and tube.

Alloy X-750 is a precipitation hardenable alloy that is super resistant to chemical corrosion and oxidation. After proper heat treatment, it has high sulfide cracking strength and low creep in high stress environments up to 816 ° C Rate of change.

The material can be used for structural parts of heat turbines, jet engines, nuclear power plant equipment and heat treatment fixtures, forming tooling, extrusion dies, etc.

Inconel X-750 Corrosion resistance

The X-750 alloy has very good resistance to stress corrosion cracking of chloride ions, and it also exhibits satisfactory resistance in various oxidizing environments. In many media, the corrosion resistance of this material is very similar to alloy 600.

Nitric acid good sulfuric acid average

Phosphoric acid General Acetic acid General

Sodium hydroxide Good Salt spray (NaCl) Good

Seawater General Acidic Oil and Gas General

Moist excellent

Inconel X-750 Physical Properties

Density: 8.44

Average specific heat: 77-212 ° F 0.1000 Btu / lb / ° F

77-1652 ° F 0.1300 Btu / lb / ° F

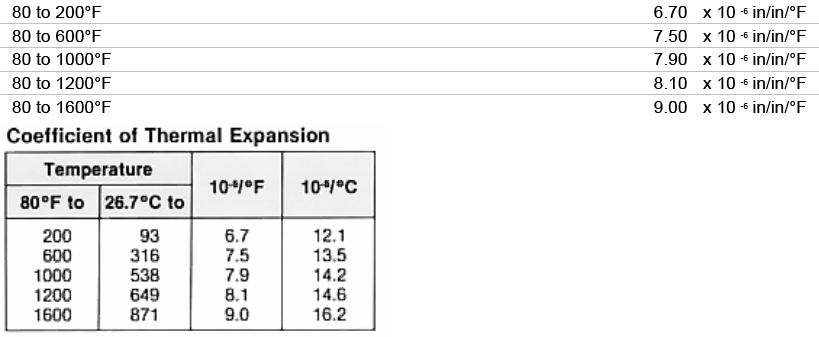

Average thermal expansion coefficient

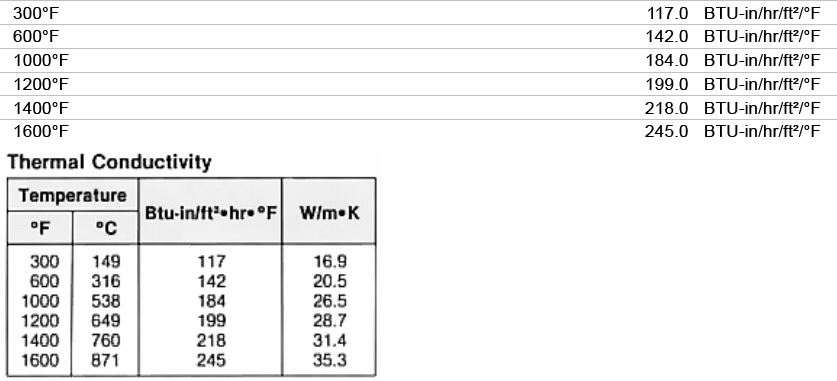

Inconel X-750 Thermal conductivity

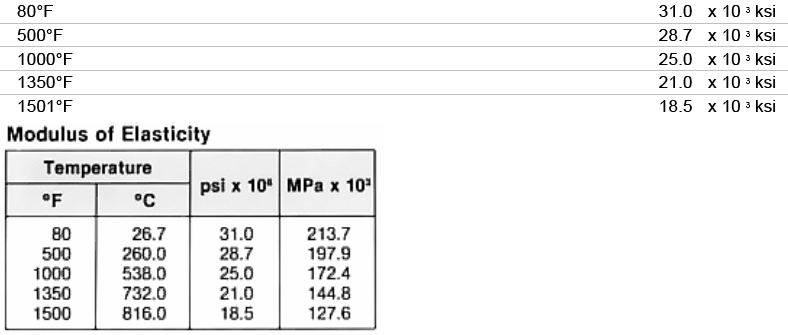

Inconel 750 Modulus of elasticity (E)

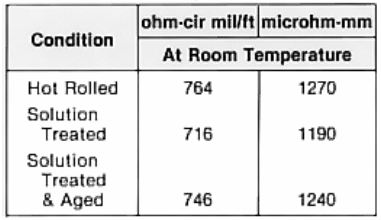

Inconel x-750 Resistance

Melting distance: 2540-2600 ° F

Mechanical behavior

Heat treatment 1: 1149 ° C solution heat treatment, 2-4 hours, air cooling; 843 ° C intermediate aging, 24 hours, air cooling; 704 ° C final aging, 20 hours, air cooling

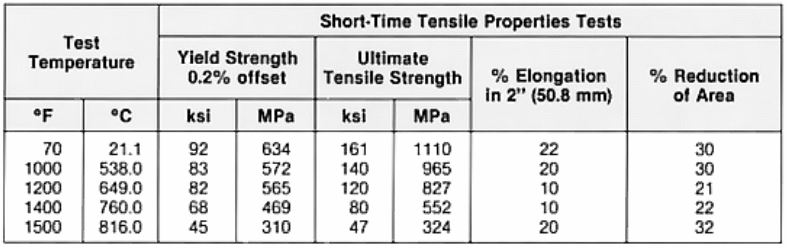

Tensile performance

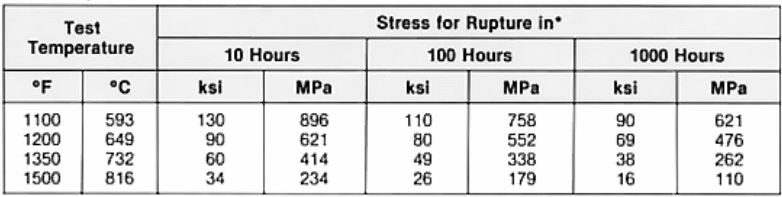

Stress cracking test data

Link to this article: What is InconelX-750

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ CNC shop produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 5 axis CNC milling available.Machining high-temperature alloy range inclouding inconel machining,monel machining,Geek Ascology machining,Carp 49 machining,Hastelloy machining,Nitronic-60 machining,Hymu 80 machining,Tool Steel machining,etc.,. Ideal for aerospace applications.CNC machining produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 3-axis & 5-axis CNC milling available.We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ CNC shop produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 5 axis CNC milling available.Machining high-temperature alloy range inclouding inconel machining,monel machining,Geek Ascology machining,Carp 49 machining,Hastelloy machining,Nitronic-60 machining,Hymu 80 machining,Tool Steel machining,etc.,. Ideal for aerospace applications.CNC machining produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 3-axis & 5-axis CNC milling available.We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:What is InconelX-750

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^