MIM metal powder injection molding in medical device industry

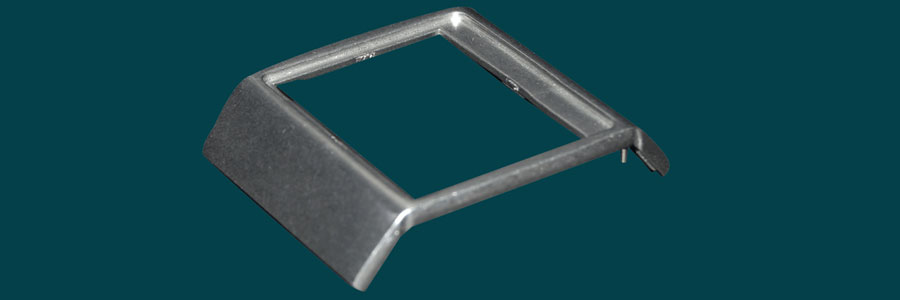

| MIM metal powder injection molding technology is a new powder metallurgy near net shape forming technology formed by combining modern plastic injection molding technology with traditional powder metallurgy process. |

It is suitable for the mass production of metal parts with small size, precision, three-dimensional shape and special performance requirements.

It has been widely used in electronic information engineering, and also in biomedical devices, or office equipment, automobiles and machinery, hardware and other materials, even in sports equipment, watch industry, weapons and aerospace. Technology has been widely recognized as the most developed industry in the world.

In the medical device industry, the rapid development of metal powder injection molding technology also shows strong power and extraordinary advantages.

A large part of medical devices are a large number of precision components and sensor materials. Because of the special nature of medical devices, they have high precision requirements for medical devices, as well as requirements for medical precision components and some sensors. The requirements for accessories are also constantly improving.

The application of powder injection molding of new technology makes the medical accessories produced with high standard precision, which can meet the requirements of most precision medical instruments for accessories, such as small size, high density and complex shape.

And with high mechanical properties and so many demanding requirements, so the medical device industry will become a huge user to drive injection molding parts, due to the strong demand for medical equipment, it is bound to drive the development of this new industry, I believe not In the distant future, medical equipment will still become an important pillar market for China’s injection molding industry to a certain extent.

Link to this article: Application of MIM metal powder injection molding in medical device industry

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:Application of MIM metal powder injection molding in medical device industry

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^