A research team led by Tao Tao, associate professor of materials science and engineering at the University of Virginia, made two discoveries that could expand additive manufacturing in aerospace and other industries that rely on strong metal parts.

According to a report by the Manufacturing Technology Association, additive manufacturing has contributed to aircraft production over the years. However, additive manufacturing also creates defects in the microstructure of the final part, which limits its role to the manufacture of pipes, internal components and other non-critical parts. The additive manufacturing of safety-regulated parts will help the aviation industry realize its desire for effective and stable supply chain management, as well as the fuel savings and emission reductions that come with light aircraft.

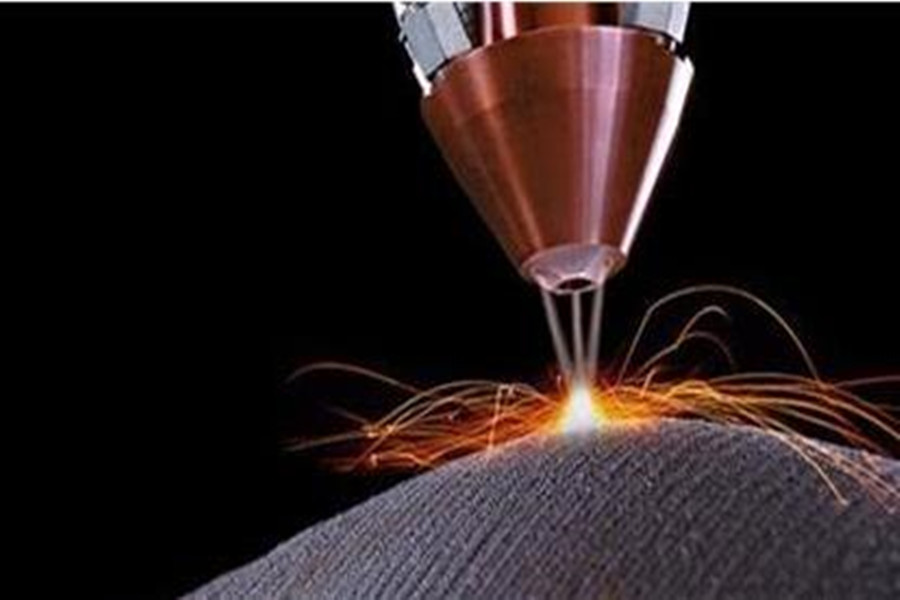

Sun’s team and collaborators have discovered why structural defects occur in the additive manufacturing of parts made of high-strength, light-weight titanium alloys that are widely used in aerospace applications. They provide process drawings, blueprints for the machines to make parts, and help manufacturers avoid defects in a common additive manufacturing technique called laser powder bed fusion.

The team’s paper “The critical instability of the tip of a moving small hole creates pores in laser melting” has been published in the November 27th issue of “Science”. Zhao Cang was a postdoctoral fellow in the Sun research group at Argonne National Laboratory and is now a faculty member of the Department of Mechanical Engineering at Tsinghua University in Beijing. He is co-authoring a thesis with colleagues from Carnegie Mellon University Argonne University, Utah and UVA . The second author, Niranjan D. Parab, is also one of the postdoctoral fellows at Sun’s Argonne National Laboratory and has since joined Intel.

The research team focused on the two most important conditions of the additive manufacturing process, namely laser power and scanning speed. The setting and interaction of these two conditions are captured in the power-speed process diagram. Similar to the conventional map, the power-speed map sets a boundary line between the area to be worked and the area to be avoided.

The power-speed graph can be divided into a good area and three bad areas. If the manufacturer stays in a good area, the part is likely to consistently produce high-quality parts. The two bad areas are easy to identify. One is the phenomenon of lack of fusion, which is evidenced by the unmelted powder caused by insufficient laser power density. When a single print line rolls on itself, the second bad area is represented by a ball, which indicates that the laser is moving too fast.

Sun and the team focused on the fourth zone. In this area, the part will have tiny holes when it comes out of the manufacturing process. This structural defect is called a pore. These tiny holes appear inside the material, making it difficult to see and control. Sun said: “You can print multiple test lines, and you still don’t know if there are still pores on the surface of the part.”

Pore defects remain a challenge for fatigue-sensitive applications such as aircraft wings. Under high power, low scanning speed laser melting conditions, some pores are related to deep and narrow vapor depressions called keyholes.

Sun and his team have discovered how the pores are generated and can characterize the transformation of materials with high spatiotemporal resolution during the 3D printing process. They used an imaging technique called high-speed synchrotron X-ray imaging, which monitors the formation of holes frame by frame throughout the laser printing process. Capturing images at microsecond intervals is far beyond what the human eye can capture or the human brain can process.

High-speed synchrotron X-ray imaging is the only available method to qualitatively measure and describe what happens when a laser beam is exposed to a bed of metal powder. In addition to melting powder, the laser will also evaporate some metal. The high-speed steam escapes the surface of the molten pool, forming a small cavity called a keyhole.

The formation and size of the keyhole depends on the laser power and the ability of the material to absorb laser energy. If the keyhole wall is stable, it will enhance the laser absorption of the surrounding materials and improve the efficiency of laser manufacturing. However, if the wall shakes or collapses, the material will solidify around the keyhole, trapping the air pocket in the newly formed layer of material. This makes the material more brittle and easier to crack under ambient pressure.

Sun describes the boundary between the good area and the bad pore area as smooth and clear. “Under very narrow laser conditions, a specific combination of power and speed separates a good part from a part with pores. Just cross the boundary between the good zone and the bad zone to determine whether your part is With this structural flaw,” Sun said. Based on the physical principles of such a smooth and sharp boundary, Sun knew that a sub-process was working.

The team eventually discovered that the interaction of lasers and metals generates sound waves.

Sun explained that sound waves can interact with bubbles in liquids in different ways. Under the action of sound force, bubbles can move, deform, split or even collapse. In this study, the research team found that under laser conditions close to the boundary of the aperture region, sound force plays a vital role in pushing the aperture away from the tip of the keyhole. In the absence of sound waves in the molten pool, the aperture will be pulled back into the keyhole.

“This is really surprising,” Sun said. “Short-pulse lasers are considered to be the source of sound waves in liquids, but we have observed acoustic effects when using continuous wave lasers. Obviously, there are still many interesting issues that need further study.”

The two discoveries described in “Science” magazine have a direct impact on metal laser additive manufacturing in the field of basic and applied research. The clearly defined boundary of the pore area in the power-speed graph provides laser powder bed fusion technicians with greater confidence in determining good printing conditions. At the same time, the new observations provided by synchrotron X-ray imaging have opened up exciting multidisciplinary research fields, which will attract more scientists to conduct basic research on laser additive manufacturing.

Sun’s research team at UVA will continue to apply the most advanced characterization techniques to conduct in-depth research on additive manufacturing processes and materials. Additive manufacturing technology is expected to revolutionize the way we manufacture.

“Additive manufacturing can only reach its full potential after the research community puts together all the beautiful physical principles that control the complex energy-material interactions involved in the printing process.”

The co-authors of the research team are Anthony Rollett, professor of materials science and engineering at Carnegie Mellon University; Kamel Fezzaa, a physicist at Arkham National Laboratory; and University of Judah Wenda Tan, Assistant Professor of Mechanical Engineering; Dr. Li and Ph.D. Student of the Department of Mechanical Engineering at the University of Utah.

Link to this article:

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. Large scale machining Manufacturer of medical bags, providing 3D design, prototype and global delivery services. Also offering hard cases, semi-hard EVA, soft-sewn cases, pouches and more for OEMs. All cases are made custom according to specifications with infinite combinations of materials, molds, pockets, loops, zippers, handles, logos and accessories. Shockproof, water-resistant and eco-friendly options. Medical parts, emergency response, Electronic parts, corporate, education, military, security, sports, outdoors and construction industries. Services include case concept consultation, 3D design, prototyping,rototyping,CNC Drilling Services and manufacturing.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. Large scale machining Manufacturer of medical bags, providing 3D design, prototype and global delivery services. Also offering hard cases, semi-hard EVA, soft-sewn cases, pouches and more for OEMs. All cases are made custom according to specifications with infinite combinations of materials, molds, pockets, loops, zippers, handles, logos and accessories. Shockproof, water-resistant and eco-friendly options. Medical parts, emergency response, Electronic parts, corporate, education, military, security, sports, outdoors and construction industries. Services include case concept consultation, 3D design, prototyping,rototyping,CNC Drilling Services and manufacturing.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

Link to this article:Contribute to the expansion of additive manufacturing in aerospace and other industries that rely on strong metal parts

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^