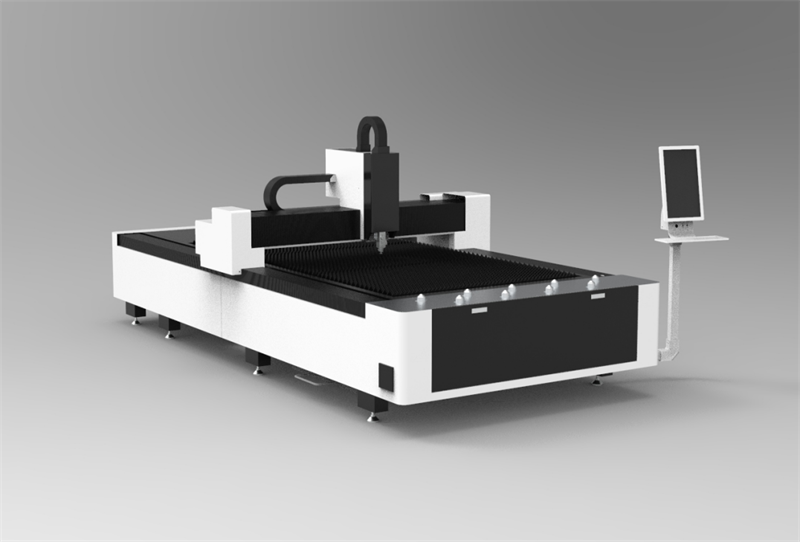

Sheet metal is used in many industries due to its light weight, high strength, electrical conductivity (ability to be used for electromagnetic shielding), low cost and good mass production performance. Laser processing technology is a non-contact cutting process, the energy and speed of the high-energy laser beam can be adjusted to achieve a variety of metal processing, the reason for the large-scale application of fibre laser Cutting Machine in the sheet metal industry, and its unique cutting advantages related to its own, the following follow China cut to understand the advantages of fibre laser cutting machine processing. ① the use of laser cutting machines for laser processing, can effectively improve production efficiency, increase economic returns, to ensure product quality ② can increase the cutting efficiency and cutting range through different media, can be a variety of processing of workpieces in closed containers; in the harsh environment of the place can also be used for robot laser processing.③Laser processing can reduce costs by eliminating “tool” wear and modular limitations.④A wide range of metals and non-metals can be processed, especially materials with high hardness, brittleness and high melting points.⑤ The laser beam is easy to guide and focus, enabling conversion to match the CNC system, making it a very flexible processing method.⑥No contact processing, no direct impact on the workpiece, so no mechanical deformation, and the high energy laser beam energy and its moving speed can be adjusted, so that a variety of processing purposes can be achieved.⑦ In laser processing, the laser beam has a high energy density, the speed can be maintained at a high rate because of the local processing, and then, because of the small heat affected zone, the heat deformation of the workpiece is reduced and the need for subsequent tedious processing is avoided.⑧Low-cost and compact solution, using a semiconductor fibre as the laser generation medium, no laser generation gas is required, which is environmentally friendly;Guangdong China cut CNC Machinery Co., Ltd. is a high-tech industry enterprise specialized in researching, manufacturing and selling the machines as follows: Laser Engraver, Fiber Laser Marking Machine, CNC Router. The products have been widely used in advertisement board, crafts and molding, architecture, seal, label, woodcutting and engraving, stonework decoration, leather cutting, garment industries, and so on. On the base of absorbing the international advanced technology, we provide the clients the most advanced production and perfect after-sale service. In recently years, our products have been sold not only in China, but also as far as Southeast Asia, Middle east, Europe, South America and other overseas Markets.Email: [email protected]

① the use of laser cutting machines for laser processing, can effectively improve production efficiency, increase economic returns, to ensure product quality ② can increase the cutting efficiency and cutting range through different media, can be a variety of processing of workpieces in closed containers; in the harsh environment of the place can also be used for robot laser processing.③Laser processing can reduce costs by eliminating “tool” wear and modular limitations.④A wide range of metals and non-metals can be processed, especially materials with high hardness, brittleness and high melting points.⑤ The laser beam is easy to guide and focus, enabling conversion to match the CNC system, making it a very flexible processing method.⑥No contact processing, no direct impact on the workpiece, so no mechanical deformation, and the high energy laser beam energy and its moving speed can be adjusted, so that a variety of processing purposes can be achieved.⑦ In laser processing, the laser beam has a high energy density, the speed can be maintained at a high rate because of the local processing, and then, because of the small heat affected zone, the heat deformation of the workpiece is reduced and the need for subsequent tedious processing is avoided.⑧Low-cost and compact solution, using a semiconductor fibre as the laser generation medium, no laser generation gas is required, which is environmentally friendly;Guangdong China cut CNC Machinery Co., Ltd. is a high-tech industry enterprise specialized in researching, manufacturing and selling the machines as follows: Laser Engraver, Fiber Laser Marking Machine, CNC Router. The products have been widely used in advertisement board, crafts and molding, architecture, seal, label, woodcutting and engraving, stonework decoration, leather cutting, garment industries, and so on. On the base of absorbing the international advanced technology, we provide the clients the most advanced production and perfect after-sale service. In recently years, our products have been sold not only in China, but also as far as Southeast Asia, Middle east, Europe, South America and other overseas Markets.Email: [email protected]

WeCha/WhatsApp: +868870255

Link to this article:Fiber laser cutting machine processing advantages

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^