Hybrid Subtractive Additive System Expert Hybrid Manufacturing Technology (HMT) revealed that it will take the lead in launching a new R&D program called “FastWireAM”.

With the support of British technology accelerator Innovate UK, the project aims to fast track the development of a new compact wire feeding system based on laser 3D printing. Once the new DED design is ready, HMT will work with consulting company TWI and welding wire raw material producer Epoch Wires to optimize its performance and accelerate its market share.

HMT has partnered with TWI and Epoch to develop a new wire feeding system for laser 3D printing.

During the research program, HMT will work with Epoch to build a new system at the Yorkshire base of technology company TWI. The British company will integrate the device into its KUKA robot cell, and plans to use the cell to perform process optimization and performance mapping tests on a dedicated demonstrator.

After TWI has verified the functions of the system as an independent third party, the two companies will 3D print a series of industrial case study components. Using these prototype parts, HMT ultimately aims to demonstrate the advantages of 3D printing over existing DED technology through its proprietary interchangeable print head.

Epoch’s participation also has a marketing element, as it intends to showcase the “added value” customers expect from its powder-cored welding wire raw materials. Although the partners have not yet confirmed the completion date of the project, they have received a grant from Innovate UK, which will accelerate the development of the equipment.

Last year, HMT used its PE-1 DED head for 3D printed parts, with a quality similar to injection molding.

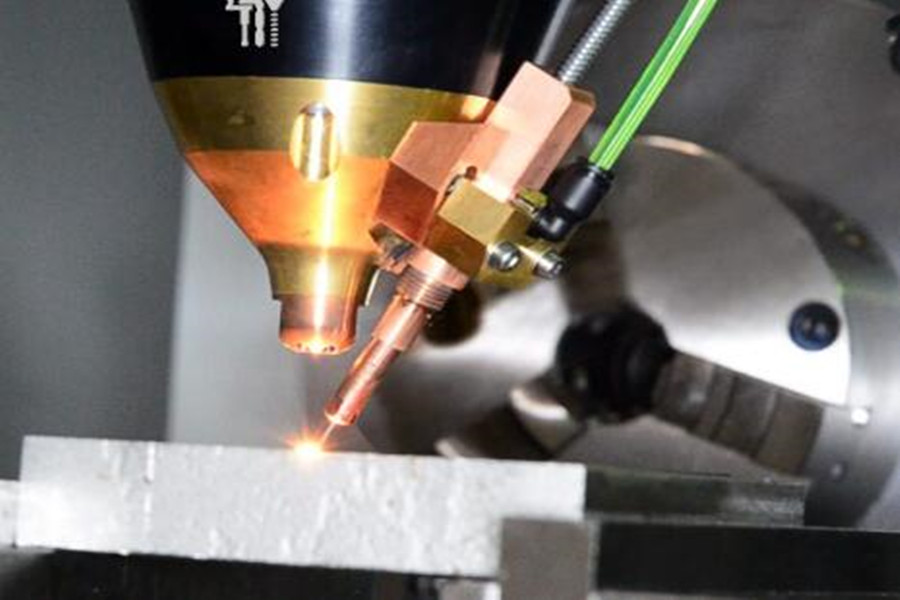

Hybrid manufacturing method of HMT

Founded in 2012, HMT is committed to combining 3D printing and milling through the marketing of its unique AMBIT DED head. Due to the unique integrated design of the equipment, users can use additive and subtractive technology to manufacture parts without adjusting the structure of the CNC machine tool.

Since the development of the original AMBIT, the company has released a series of tool heads, inspection heads and laser scanners designed to provide customers with the best process versatility. The company is also involved in other areas of 3D printing and developed its new “AXIOM” thermoplastic production method in May 2020.

HMT’s hybrid process aims to combine the speed and part quality advantages associated with injection molding with additive manufacturing to find a new “middle ground.” The company discovered a new method when connecting its AMBIT XTRUDE PE-1 print head to a CNC machine tool while producing PPE last year.

It is said that the surface finish of many of the resulting parts is similar to that of injection molded parts. Although XTRUDE PE-1 itself is nothing new and has been connected to various robotic platforms, this new approach at least reflects the company’s commitment to continuously improving its technology.

The British government established Innovate UK to promote the development of advanced technology and often provides funding for projects based on 3D printing.

In December last year, Meta Additive received a £1.2 million grant from Innovate UK to further develop its novel proprietary adhesive jetting technology. According to reports, the process can achieve higher part density and lower shrinkage, making it ideal for aerospace or medical 3D printing applications.

Blue Tap, a derivative product of the University of Cambridge, also received funding from the British Innovation Foundation to support the technological development of its 3D printing water purification technology. The company’s additive chlorine meter is designed for use in pipeline water supply systems in developing countries.

In the past, Innovate UK also established a project call and launched a £2 million funding competition in March 2019 to help further research photonics technology. A part of the R&D grant is reserved for advancing laser processing, 3D printing, photon curing or LiDAR processes.

Link to this article: New wire feeding system for laser-based 3D printing

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. Large scale machining Manufacturer of medical bags, providing 3D design, prototype and global delivery services. Also offering hard cases, semi-hard EVA, soft-sewn cases, pouches and more for OEMs. All cases are made custom according to specifications with infinite combinations of materials, molds, pockets, loops, zippers, handles, logos and accessories. Shockproof, water-resistant and eco-friendly options. Medical parts, emergency response, Electronic parts, corporate, education, military, security, sports, outdoors and construction industries. Services include case concept consultation, 3D design, prototyping,rototyping,CNC Drilling Services and manufacturing.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. Large scale machining Manufacturer of medical bags, providing 3D design, prototype and global delivery services. Also offering hard cases, semi-hard EVA, soft-sewn cases, pouches and more for OEMs. All cases are made custom according to specifications with infinite combinations of materials, molds, pockets, loops, zippers, handles, logos and accessories. Shockproof, water-resistant and eco-friendly options. Medical parts, emergency response, Electronic parts, corporate, education, military, security, sports, outdoors and construction industries. Services include case concept consultation, 3D design, prototyping,rototyping,CNC Drilling Services and manufacturing.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

Link to this article:New wire feeding system for laser-based 3D printing

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^