Successful foam extrusion looks like art. The optimized foam process using inert gases saves materials and energy, without causing global warming or the potential for ozone depletion. Facts have proved that thermoplastic foam extrusion is beneficial to the extrusion of rigid profiles, wood and sheet materials, as well as cables, garden hoses and films. However, these six basic rules are usually ignored.

Carbon dioxide and/or nitrogen introduced by chemical blowing agent (CFA) or direct gas injection (sometimes used in combination) is one of many gases. These gases are usually the first choice for medium-density and high-density foams because they are non-corrosive, non-toxic and non-flammable. Even if these gases promote a moderate density reduction, they can also save costs. The most important of these is that energy consumption can be significantly reduced by optimizing the foam extrusion process.

In this article, the editor of Xianji.com will focus on the chemical foaming of high-density panels.

1. Choose the right product for the job

Not all CFAs meet all standards for all polymers. The decomposition temperature of CFA must be close to the processing temperature of the polymer. The gas must be released within a specific, rather narrow temperature range, and should have a sufficiently large volume, and can be controlled by temperature and pressure. The gas must have time to completely disperse in the polymer. The extruder with L/D of 24:1 is the minimum length allowed.

The diffusion rate of the gases released during the decomposition of CFA in the polymer must be low so that they remain in the plastic block long enough to allow it to cool and harden. It is also important that the carrier resin that is miscible with the CFA masterbatch can be miscible with the selected resin. Generally, a treatment temperature of about 25-35°F higher than the starting temperature of CFA decomposition will ensure complete activation and complete dispersion without agglomeration and irregular cell structure. Damaged battery structures may result in poor thermoforming, which can lead to weakened corners and limit the depth of extension.

2. Much less

It is often misunderstood that if 1% of a given CFA achieves a 15% density reduction, then 2% of the same product should result in a 30% density reduction, but this is usually not the case. In fact, as the density increases, the more you add, the further away you may be from the target. You can quickly reach the point of uncontrollable growth of the bubbles when they leave the die, causing the die to expand and the contour to fail to maintain its expected shape.

Or, bubbles may grow excessively in the melt, thereby forming open pores where they need to be closed. The bubbles will then coalesce and burst, resulting in higher density than expected or desired. In the end, the part will not have the appearance or performance as it was designed. It is best to determine the level of CFA that can be fed uniformly and achieve controlled performance of the equipment.

3. Bell-shaped temperature curve

When extruded with a blowing agent under sufficient internal barrel pressure, it will lower the glass transition temperature (Tg) of the polymer. It is usually difficult to convey this fact to people who have not started, but the gas released by CFA (CO2 or N2) acts as a plasticizer, reducing the viscosity of the polymer. For example, an unfoamed PE sheet may extrude the entire profile at a speed of 400 F. However, during the foaming process, the profile of the same polymer (from the feed zone to the die) may be 340, 360, 380, 400, 380F.

Note the “bell profile”. By sending it into a cool area, you can prevent premature foaming, which can cause gas to escape from the feed throat. In zone 4, you have fully activated the CFA. And through the mold exit, you have already formed the sheet while starting the cooling process. The temperature of the melt at the outlet should be optimized so that the expansion does not deform.

4. Barrier-free screws

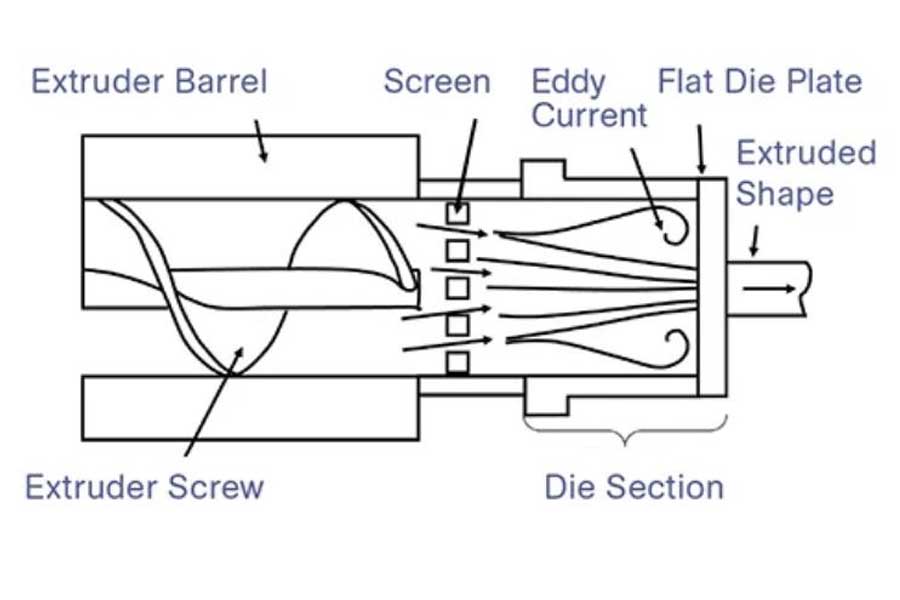

The screw is the main method for pumping resin and CFA and turning them into a homogeneous melt. Conventional screws are divided into three different working parts: the feeding part, the transition part and the metering part.

Spacer screws are sometimes used to prevent material from flowing back into the feed area, but they can hinder your foaming process. The barrier layer will act as a decompression zone, leading to gas loss or early battery generation, resulting in poor density reduction or ugly ejection from the surface of the sheet. For the same reason, please close the vent of the extruder.

5. Pull the screen

Or at least use a rough screen. Screens are usually used to increase pressure and/or prevent caking, but are usually not needed during the foaming process. A screen that is too fine will rupture the cells and destroy the bubble structure. The screen can be completely removed, but if a screen must be used, a 20/40/20 grid is usually acceptable.

6. Optimize the foam mold

When the resin is conveyed along the screw, the mold design becomes a key component of producing high-quality foam. For sheet materials, slot molds with “hanger” manifolds are usually used. In the standard non-foaming extrusion process, the main function of the mold is to shape the extrudate after plasticization (melting). But during the foaming process, the role of the mold is transformed to prevent the foam from expanding before it exits, and only to guide the overall shape defined by the calibrator.

The angle of the foam mold and the length of the cutting edge have been optimized to minimize the pressure drop that can cause early foaming. The foam mold outlet is usually smaller than the size of the finished part, so that it grows outward when it leaves the mold. If the goal is to reduce the density by 20%, the mold should be 20% smaller than the expected final shape. When the sheet enters the cooling phase, the shorter mold area will allow a single rapid expansion. Adequate cooling after expansion will minimize gas diffusion and solidify the sheet to its intended size.

Link to this article:

Six rules to prevent thermoplastic foam board from extruding speed collection!

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:Six rules to prevent thermoplastic foam board from extruding speed collection!

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^