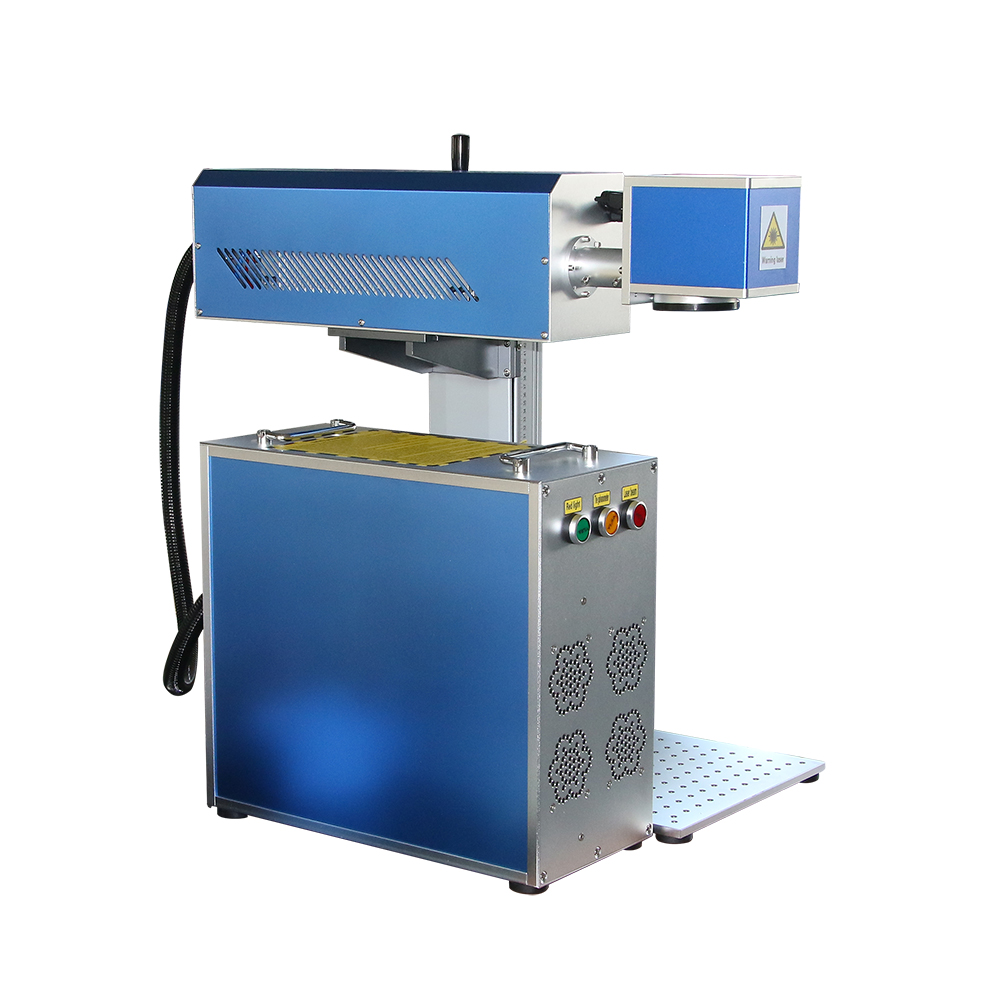

Wood is a commonly used material for laser processing and the use of laser machines to process wood is becoming increasingly popular with related industries. Laser processing of wood, which is easy to engrave and cut, has the advantages of short processing times, high processing accuracy and low costs. As each type of wood has its own characteristics, the corresponding processing method is also different. If you are not too familiar with the carving of wood before, you should first understand the carving characteristics of the equipment, the following follow the China cut laser to see. The new generation of carbon dioxide non-metal laser marking machine is small in size and faster.The CO2 laser labeling unit laser is a gas laser with an infrared light frequency band wavelength of 10.64m. As the medium for producing the laser, carbon dioxide gas is charged into the discharge channel. A glow discharge is produced in the discharge tube when a high voltage is applied to the electrode. The light is emitted by the gas molecule, and the laser energy is intensified to create a laser beam for material processing. The computer modifies the laser beam direction in order to monitor the galvanometer and achieve automatic labeling. The CO2 laser marking system is equipped with a carbon dioxide laser imported from the United States, a high-speed scanning galvanometer, a fair overall structure design, quick speed, high accuracy, a safe and efficient machine, a long component life, and a low product depreciation rate.It is commonly used for graphic and text labeling and cutting in textile accessories, acrylic, leather, food and beverage packaging, electrical parts, handicraft manufacturing, glass and stone processing, and other areas.The laser engraving machine’s technological approach for engraving wood materials-grayscale results Since ordinary mechanical engraving cannot economically engrave points of varying thicknesses, it lacks a grayscale expression. The laser engraving machine engraves by dotting, which provides a natural advantage in grayscale results.

The CO2 laser marking system is equipped with a carbon dioxide laser imported from the United States, a high-speed scanning galvanometer, a fair overall structure design, quick speed, high accuracy, a safe and efficient machine, a long component life, and a low product depreciation rate.It is commonly used for graphic and text labeling and cutting in textile accessories, acrylic, leather, food and beverage packaging, electrical parts, handicraft manufacturing, glass and stone processing, and other areas.The laser engraving machine’s technological approach for engraving wood materials-grayscale results Since ordinary mechanical engraving cannot economically engrave points of varying thicknesses, it lacks a grayscale expression. The laser engraving machine engraves by dotting, which provides a natural advantage in grayscale results. Ordinary mechanical engraving cannot be engraved in an economical way with thick and thin dots, and therefore does not have a form of grey-scale expression. Laser engraving machine is to achieve carving in the form of dots, has a natural advantage in the performance of greyscale, on the one hand, to reduce the colouring process, saving costs; on the other hand, to enrich the means of expression of the carving, increasing the level of graphics. For the use of laser machines for processing wood, as long as you pay attention to these points can be well mastered to use, the processing of wood will also be very good results.Guangdong China cut CNC Machinery Co., Ltd. is a high-tech industry enterprise specialized in researching, manufacturing and selling the machines as follows: Laser Engraver, Fiber Laser Marking Machine, CNC Router. The products have been widely used in advertisement board, crafts and molding, architecture, seal, label, woodcutting and engraving, stonework decoration, leather cutting, garment industries, and so on. On the base of absorbing the international advanced technology, we provide the clients the most advanced production and perfect after-sale service. In recently years, our products have been sold not only in China, but also as far as Southeast Asia, Middle east, Europe, South America and other overseas Markets.Email: [email protected]

Ordinary mechanical engraving cannot be engraved in an economical way with thick and thin dots, and therefore does not have a form of grey-scale expression. Laser engraving machine is to achieve carving in the form of dots, has a natural advantage in the performance of greyscale, on the one hand, to reduce the colouring process, saving costs; on the other hand, to enrich the means of expression of the carving, increasing the level of graphics. For the use of laser machines for processing wood, as long as you pay attention to these points can be well mastered to use, the processing of wood will also be very good results.Guangdong China cut CNC Machinery Co., Ltd. is a high-tech industry enterprise specialized in researching, manufacturing and selling the machines as follows: Laser Engraver, Fiber Laser Marking Machine, CNC Router. The products have been widely used in advertisement board, crafts and molding, architecture, seal, label, woodcutting and engraving, stonework decoration, leather cutting, garment industries, and so on. On the base of absorbing the international advanced technology, we provide the clients the most advanced production and perfect after-sale service. In recently years, our products have been sold not only in China, but also as far as Southeast Asia, Middle east, Europe, South America and other overseas Markets.Email: [email protected]

WeCha/WhatsApp: +868870255

Link to this article:Technical explanation of laser engraving of different woods

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^