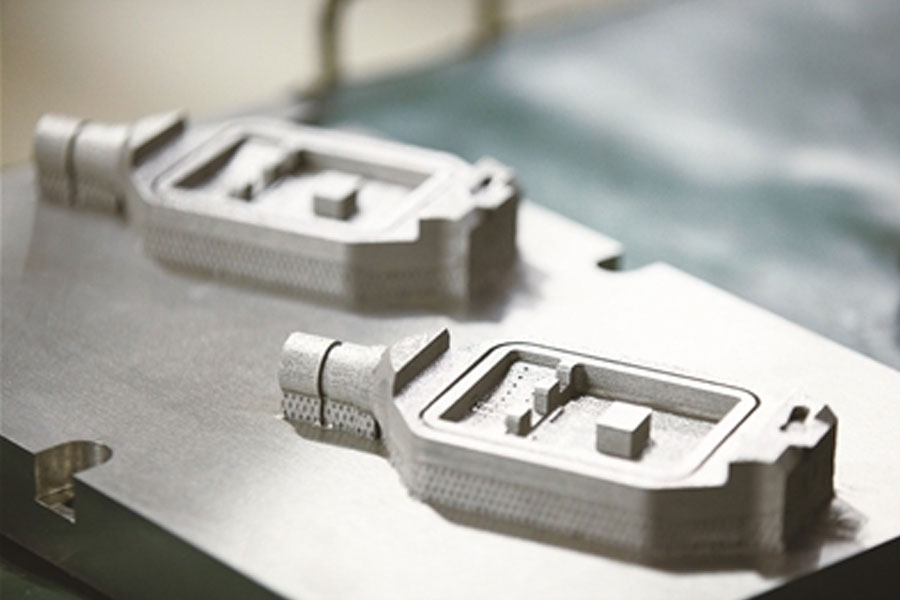

CNC milling machines are mechanical equipment used to manufacture molds, inspection fixtures, molds, thin-walled complex curved surfaces, artificial prostheses, blades, etc., and the advantages and key roles of CNC milling machines should be fully utilized when choosing CNC milling.

During NC programming, the programmer must determine the cutting parameters for each process, including the spindle speed and feed speed. Different cutting parameters need to be selected for different methods. The following briefly introduces the parameter selection scheme of the milling process:

The determination of the spindle speed

The spindle speed should be selected according to the allowable cutting speed and the diameter of the workpiece. Finally, the calculated spindle speed should be selected according to the machine tool manual.

The determination of the feed rate

Feed speed is an important parameter in the cutting parameters of CNC machine tools, which is mainly selected according to the accuracy and surface roughness requirements of the parts and the material properties of the workpiece. The feed rate is limited by the rigidity of the machine tool and the performance of the feed system. When the contour is close to the corner, the feed rate should be appropriately reduced to overcome the phenomenon of “overtravel” or “undertravel” at the corner of the contour due to inertia or deformation of the process system.

The principle of determining the feed rate

- (1) When the quality of the workpiece can be guaranteed, in order to improve efficiency, a higher feed rate can be selected.

- (2) When cutting, deep hole or high-speed steel, a lower feed rate should be selected.

- (3) When the precision and surface roughness are required to be high, the feed speed should be smaller.

- (4) When idling, especially for long-distance “zero return”, the feedrate given by the CNC system of the machine tool can be selected.

Eat back. The amount is determined

The amount of back feed is determined according to the rigidity of the machine tool, work piece and tool. In order to ensure the surface quality, a fine work margin can be left. If the rigidity permits, the amount of back-feeding should be equal to the margin of the workpiece as much as possible, so that the number of walks can be reduced and the efficiency can be improved.

Thread milling. Main types

(1) Cylindrical thread milling.

Cylindrical thread milling. The shape is very similar to the combination of cylindrical end milling and thread tap, but its thread cutting edge is different from the tap. The spiral lift in the non-helical lift is realized by the movement of the machine tool. Because of this special structure, the tool can be used for both right-handed and left-handed threads, but it is not suitable for larger-pitch threads.

(2)Machine clamp thread milling and piece

Machine clamp thread milling. Suitable for larger diameter threads. Its characteristic is that the chip is easy to manufacture, and some threads can be cut on both sides, but the impact resistance is slightly worse than that of integral thread milling. Therefore, this tool is often recommended for aluminum alloy materials.

(3)Combined multi-station special thread boring and milling

Combined multi-station special thread boring and milling is characterized by a multi-edge, multiple stations can be completed at one time, which can save auxiliary time such as replacement and significantly improve efficiency.

Thread milling track

The thread milling motion track is a spiral line, which can be realized by the three-axis linkage of the CNC machine tool. Like the CNC milling of general contours, circular arc cutting or linear cutting can also be used when thread milling starts. When milling, you should try to choose a milling piece whose width is greater than the length of the thread to be machined. Milling only needs to rotate to complete the thread.

The above is the formulation plan of the milling process parameters to ensure the accuracy and surface roughness of the parts, give full play to the cutting performance, ensure reasonable durability and give full play to the performance of the machine tool.

Link to this article:The Correct Selection Method Of Milling Machining Parameters

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:The Correct Selection Method Of Milling Machining Parameters

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^