As additive manufacturing (AM) becomes more and more common in manufacturing, many traditional manufacturers are considering applying it to certain applications even in high-volume environments. However, jumping into a whole new field of manufacturing can be daunting, and it will be much easier with the guidance of experienced personnel.

John Nanry, co-founder and CEO of Fast Radius, said: “There are many myths surrounding AM.” Determining whether AM is suitable for your application means breaking these myths and making decisions based on the current state of AM.

Is the additive material reliable?

In the manufacturing sector, the quality of parts is as good as the material they are made of, and the fragility or porosity of AM parts often makes manufacturers see it as a disadvantage. Although this view was well-founded in the early days of AM, the process is no longer limited to prototypes. Many modern additive materials have isotropic or close to isotropic mechanical properties, making their structure similar to injection-molded plastics.

Today, many additive manufacturing materials can directly compete with traditional polymers. For example, CE 221 can replace many brittle materials, including epoxy and composite materials. For ductile materials, RPU 70 can compete with polyurethane and polycarbonate, while EPU 40/41 can compete with superelastic materials such as rubber and elastomers. Generally, additive manufacturing materials can outperform traditional materials.

Even older AM plastics have been successful in mass production. For example, in the aerospace field, the performance of the polyetherimide ULTEM has obtained FAA certification for non-critical components. This material is commonly used in Fused Deposition Modeling (FDM), and its strength/weight ratio is similar to some aluminum alloys, which makes it ideal for replacing certain heavy metals and weaker plastics.

Of course, the characteristics of additively manufactured parts depend not only on the material, but also on the technology. Nanry said: “While early layer-by-layer 3D printing technology usually produced parts that lacked consistent directional density, newer methods such as barrel polymerization and powder bed fusion (PBF) produced higher density and more uniformity. Parts.” Modern technology has reduced the problems that caused failures in the past, thereby improving the consistency and reliability of AM parts.

With AM being able to replace many traditional materials, the question asked by many people is simple: Can this part be added?

Can you print this part?

Many parts have strict specifications to meet the unique needs of the final product. However, additive manufacturing materials have been used in every industry from medical and aerospace to consumer products. Nanry said: “There are many additive materials that are as good as traditional plastics, or even better than traditional plastics.” “Whether you need items that withstand harsh environments or only need items with high durability, AM can meet your needs. “For example, due to the high strength/weight ratio and high maximum use temperature, materials such as epoxy 82 (EPX 82) are often used in agriculture and construction. On the other hand, rigid polyurethane 70 (RPU 70) is often used for housings due to its durability and flexibility.

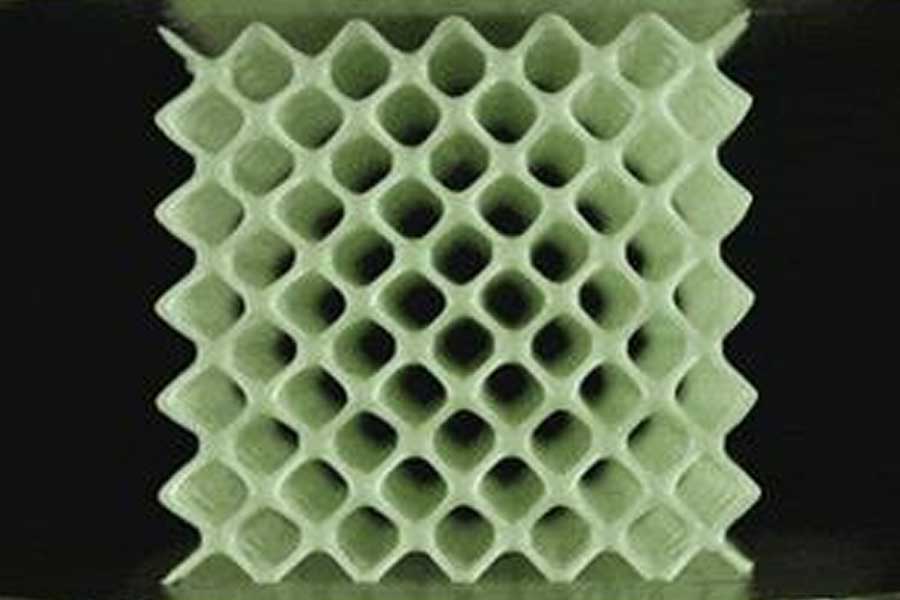

Additives can also create opportunities for new part designs. For example, AM can be used to merge parts, eliminating the need for expensive, complex components. In some cases, part reinforcement can eliminate the need to manufacture separate hinges, washers, or threaded connectors, which often improves the quality of the parts. In addition, AM makes complex lattices possible, allowing users to reduce the weight of parts without compromising their strength.

In fact, more materials are constantly being developed. For example, HP 3D High Reusability TPA is a lightweight, flexible material with enhanced resilience. In cold weather, it is also extremely brittle, keeping the performance of the elastomer below the freezing point. The combination of these characteristics makes it an ideal choice for sports in cold weather, airless tires and auto parts. Maintaining this development trend can be very profitable, because you may find materials that meet the needs of your application. Even better, new materials may inspire you to handle parts in completely new ways.

However, the availability of materials is only one problem, and the other is cost.

Is the cost of additive materials too high?

When weighing production feasibility, cost has always been the main factor, and this is also the case in AM. Although newer materials tend to have a higher cost trend than materials manufactured through traditional manufacturing techniques, technological advances will quickly drive down prices. Even in high production lines, many additive materials have reached the point of cost-effectiveness.

Even if prices fall, the unit cost of additive manufacturing materials may still be high, which is understandable if this deters some manufacturers. However, materials are not the only cost of manufacturing parts. Nanry said: “It is important to evaluate the complete cost structure of additive manufacturing parts.” “Calculating the total cost (including factors such as tooling, machining, and storage) shows that in some cases, the cost of additives may be significantly lower than that of CNC machines. Processing or injection molding.”

When materials and technology are constantly changing, outsiders may be discouraged. Nanry said: “It helps to keep up with the times, or to work with accomplished people.”

Link to this article: The development of additive polymers helps traditionally manufactured parts turn to 3D printing

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Link to this article:The development of additive polymers helps traditionally manufactured parts turn to 3D printing

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^