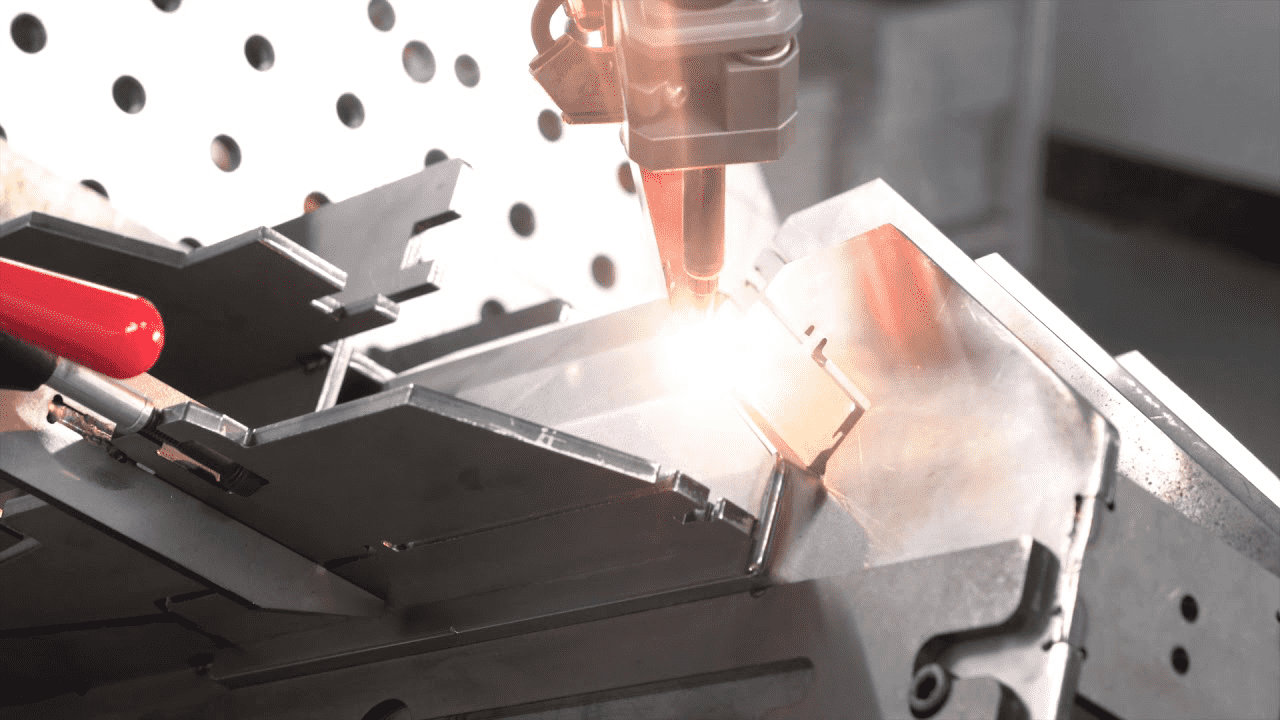

Due to the continuous development of society, the requirements of industrial technology for materials tend to diversify, and the traditional welding methods can no longer meet these needs. With the continuous development of laser technology, laser welding technology has gradually become the most advanced welding method in the processing field with the advantages of fast welding speed, high strength, narrow weld seam, small heat-affected zone, and small deformation of the workpiece, less workload for subsequent processing, reduced manual output, high flexibility, and more safety. Compared with traditional welding technology, laser welding technology is non-contact welding, the operation process does not require pressure, can be used to weld refractory materials such as high melting point metals, and can even be used for non-metallic materials such as ceramics, organic glass and other welding, welding of shaped materials, good results, and has great flexibility. Laser welding methods can be divided into four types, the following follow the china mark laser to see.1、Laser brazing.Laser as a heat source, the use of materials with a lower melting point than the parent material as brazing material, after the laser melting into a liquid state and wetting the parent material, to achieve the filling of the gap between the parent material and the parent material diffusion combined with each other, and finally realize the joint, laser brazing is not only conducive to improving the aesthetics of the product, but also play a good role in strengthening the solidity of the painting body to promote.2、Laser fusion welding.Laser melting welding is the use of laser as a heat source, in the corner of two plates, each melting two plates part of the base material (while melting the nearby wire filler two plates corner), so that the formation of liquid metal, after it cools, the formation of a reliable connection welding method Laser melting welding can be specifically divided into laser fusion welding, laser fusion welding (without wire filler) and laser melting wire filler welding, etc.3、Laser remote welding.Laser remote welding is the installation of an oscillating mirror scanning head on the sixth axis of the robot, which only reflects the laser trajectory movement through the oscillating lens, without the need for the robot arm to follow the movement. The laser remote welding system is highly flexible and efficient, and one system can replace six to nine sets of common robots for spot welding. The distance between the laser head and the workpiece is more than 500mm, which can extend the service life of the lens protection glass.4、Laser composite welding.Laser composite welding mainly refers to laser and MIG arc composite welding. In this process, the laser and arc interaction, complementing each other’s strengths, high welding speed, stable welding process and high thermal efficiency, while allowing greater welding assembly gap. The low heat input, small heat-affected zone and low deformation of the workpiece greatly reduce the need for post-weld deformation correction. Guangdong China cut CNC Machinery Co., Ltd. is a high-tech industry enterprise specialized in researching, manufacturing and selling the machines as follows: Laser Engraver, Fiber Laser Marking Machine, CNC Router. The products have been widely used in advertisement board, crafts and molding, architecture, seal, label, woodcutting and engraving, stonework decoration, leather cutting, garment industries, and so on. On the base of absorbing the international advanced technology, we provide the clients the most advanced production and perfect after-sale service. In recently years, our products have been sold not only in China, but also as far as Southeast Asia, Middle east, Europe, South America and other overseas Markets.

Compared with traditional welding technology, laser welding technology is non-contact welding, the operation process does not require pressure, can be used to weld refractory materials such as high melting point metals, and can even be used for non-metallic materials such as ceramics, organic glass and other welding, welding of shaped materials, good results, and has great flexibility. Laser welding methods can be divided into four types, the following follow the china mark laser to see.1、Laser brazing.Laser as a heat source, the use of materials with a lower melting point than the parent material as brazing material, after the laser melting into a liquid state and wetting the parent material, to achieve the filling of the gap between the parent material and the parent material diffusion combined with each other, and finally realize the joint, laser brazing is not only conducive to improving the aesthetics of the product, but also play a good role in strengthening the solidity of the painting body to promote.2、Laser fusion welding.Laser melting welding is the use of laser as a heat source, in the corner of two plates, each melting two plates part of the base material (while melting the nearby wire filler two plates corner), so that the formation of liquid metal, after it cools, the formation of a reliable connection welding method Laser melting welding can be specifically divided into laser fusion welding, laser fusion welding (without wire filler) and laser melting wire filler welding, etc.3、Laser remote welding.Laser remote welding is the installation of an oscillating mirror scanning head on the sixth axis of the robot, which only reflects the laser trajectory movement through the oscillating lens, without the need for the robot arm to follow the movement. The laser remote welding system is highly flexible and efficient, and one system can replace six to nine sets of common robots for spot welding. The distance between the laser head and the workpiece is more than 500mm, which can extend the service life of the lens protection glass.4、Laser composite welding.Laser composite welding mainly refers to laser and MIG arc composite welding. In this process, the laser and arc interaction, complementing each other’s strengths, high welding speed, stable welding process and high thermal efficiency, while allowing greater welding assembly gap. The low heat input, small heat-affected zone and low deformation of the workpiece greatly reduce the need for post-weld deformation correction. Guangdong China cut CNC Machinery Co., Ltd. is a high-tech industry enterprise specialized in researching, manufacturing and selling the machines as follows: Laser Engraver, Fiber Laser Marking Machine, CNC Router. The products have been widely used in advertisement board, crafts and molding, architecture, seal, label, woodcutting and engraving, stonework decoration, leather cutting, garment industries, and so on. On the base of absorbing the international advanced technology, we provide the clients the most advanced production and perfect after-sale service. In recently years, our products have been sold not only in China, but also as far as Southeast Asia, Middle east, Europe, South America and other overseas Markets.

Link to this article:Laser welding machine four welding methods introduced

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^