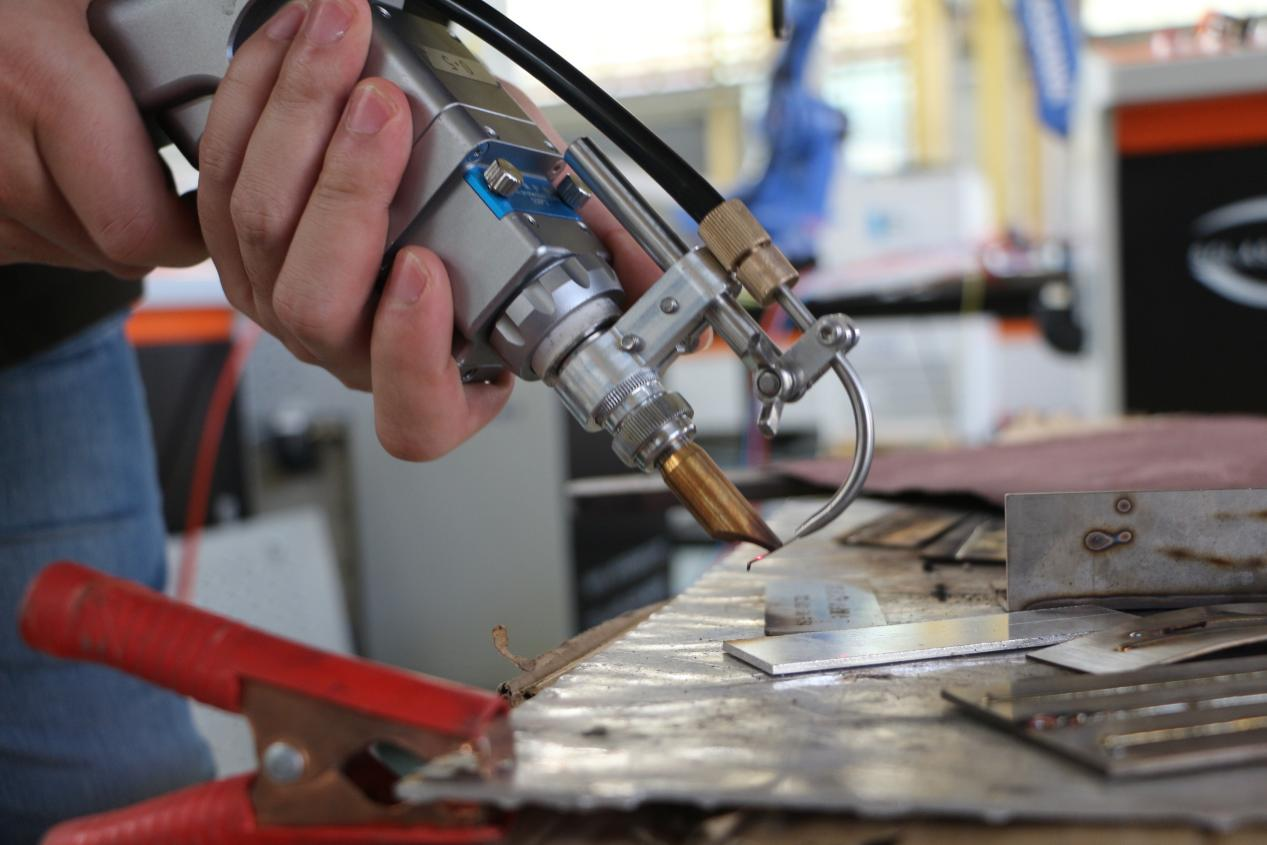

Aluminum and aluminum alloys rank first in the world production of non-ferrous metals, and in recent decades, they have occupied a pivotal position in various materials used in modern engineering technology. Aluminum alloys are mainly used in aerospace, automotive, marine and even home decoration fields because of their high strength and light weight. At present, the main welding processes of aluminum alloy welding are manual TIG welding, automatic TIG welding and MIG welding. Among them, argon arc welding is the most widely used one. However, with the development of the industry, traditional TIG welding in some areas has been unable to meet the increasing processing needs of users. Traditional argon arc welding not only requires mature technical personnel, but also limited by the slow welding speed, welding difficulty, high ozone content generated during welding, harm to human body; heat-affected area, easy to deformation, weld quality is more difficult to ensure and other adverse factors, so the development of the industry has been subject to many constraints.In recent years, with the continued progress of laser technology, the application of laser processing has become more and more extensive, and the advantages have become more and more obvious. Laser welding, as a new welding method, uses a high energy density laser beam as a heat source to locally heat the material in a tiny area, dissolving the material and forming a specific molten pool to achieve the effect of welding. After conventional welding, the welded joint often needs to be polished to ensure a smooth and uncoarse finish, while laser welding precisely reflects more advantages in the processing effect.

Traditional argon arc welding not only requires mature technical personnel, but also limited by the slow welding speed, welding difficulty, high ozone content generated during welding, harm to human body; heat-affected area, easy to deformation, weld quality is more difficult to ensure and other adverse factors, so the development of the industry has been subject to many constraints.In recent years, with the continued progress of laser technology, the application of laser processing has become more and more extensive, and the advantages have become more and more obvious. Laser welding, as a new welding method, uses a high energy density laser beam as a heat source to locally heat the material in a tiny area, dissolving the material and forming a specific molten pool to achieve the effect of welding. After conventional welding, the welded joint often needs to be polished to ensure a smooth and uncoarse finish, while laser welding precisely reflects more advantages in the processing effect. Laser welding has the following advantages.1. Fast welding speed and high processing efficiency.2. reduction of cost by not using laser filler wire.3、Reducing material deformation.4、Smooth and beautiful weld seam, reducing the subsequent grinding process.5、Stable weld surface formation, no spatter

Laser welding has the following advantages.1. Fast welding speed and high processing efficiency.2. reduction of cost by not using laser filler wire.3、Reducing material deformation.4、Smooth and beautiful weld seam, reducing the subsequent grinding process.5、Stable weld surface formation, no spatter Guangdong China cut CNC Machinery Co., Ltd. is a high-tech industry enterprise specialized in researching, manufacturing and selling the machines as follows: Laser Engraver, Fiber Laser Marking Machine, CNC Router. The products have been widely used in advertisement board, crafts and molding, architecture, seal, label, woodcutting and engraving, stonework decoration, leather cutting, garment industries, and so on. On the base of absorbing the international advanced technology, we provide the clients the most advanced production and perfect after-sale service. In recently years, our products have been sold not only in China, but also as far as Southeast Asia, Middle east, Europe, South America and other overseas Markets.Email: [email protected]

Guangdong China cut CNC Machinery Co., Ltd. is a high-tech industry enterprise specialized in researching, manufacturing and selling the machines as follows: Laser Engraver, Fiber Laser Marking Machine, CNC Router. The products have been widely used in advertisement board, crafts and molding, architecture, seal, label, woodcutting and engraving, stonework decoration, leather cutting, garment industries, and so on. On the base of absorbing the international advanced technology, we provide the clients the most advanced production and perfect after-sale service. In recently years, our products have been sold not only in China, but also as far as Southeast Asia, Middle east, Europe, South America and other overseas Markets.Email: [email protected]

WeCha/WhatsApp: +868870255

Link to this article:Laser welding makes aluminum alloy welding more efficient

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cut Wiki,Thanks!^^